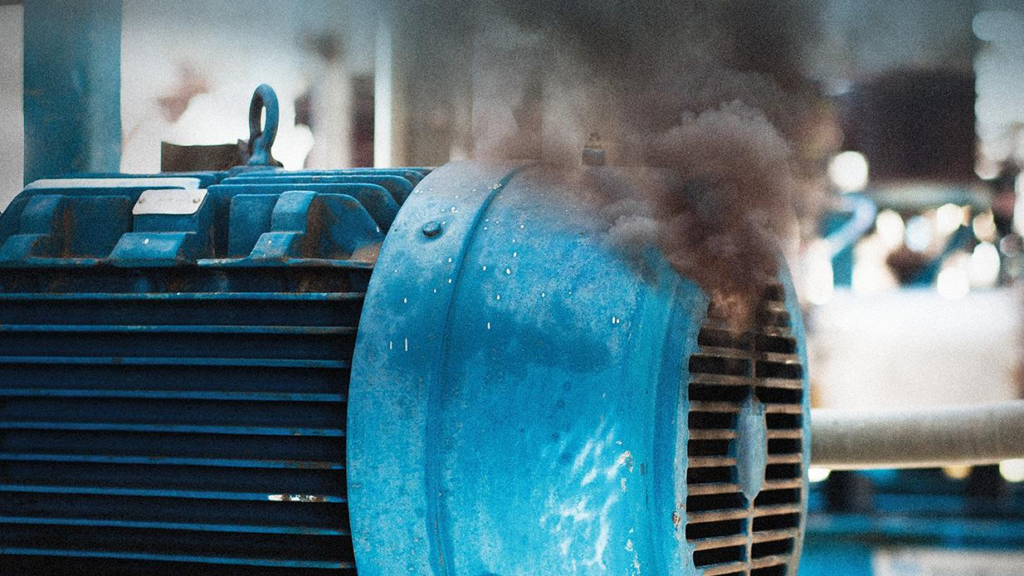

Every maintenance department’s worst nightmare is machine failure. On top of that, there’s a challenge to determine the actual cause on a limited amount of time. The equipment breakdowns detailed in this article resisted easy fixes and were extremely expensive in terms of people, materials, and downtime.

Systematic techniques, as well as the data obtained, should give you a better sense of what is happening in your equipment which you could also use in similar types of equipment failures in your facility.

Despite the lubricant’s damaged appearance, it still carries evidence from the time leading up to and including the catastrophic occurrence. A technique can sometimes be aided by sump or tank bottom sampling. The dirt collects in the tank’s bottom, forming a virtual scrapbook of the machine’s operation since the last oil change or tank cleaning.

Many of the particles will be in the early stages of wear. Others will have disastrous consequences. They may be able to assist you in piecing together the story. A word of caution: this method of sampling does not allow you to categorize the particle by the component that made it or by the moment it was created.

Filter Analysis

The filter can be used as a history book as well. It collects the particles that have been created since the last filter update and prior to the failure occurrence. The evidence of the incipient event leading up to the catastrophic failure can be examined by opening the filter, freeing the particles using an ultrasonic bath, and depositing them onto a slide or filter patch. This method, like tank bottom sampling, does not separate the particles by component or manufacturing time.

Wear Debris Sampling and Analysis

There are numerous methods for analyzing wear debris. Wear debris must first be removed from the obtained oil sample before analytical ferrography can be performed. An optical microscope is then used to examine photomicrograph pictures of ferrograms or filtergrams. The capacity to detect particle forms, sizes, and textures, as well as identify components, are the major benefits of using analytical ferrography. With an experienced analyst, these details can be used to identify the failure modes of your equipment.

Wear Modes

Rubbing Wear (Abrasive Wear)

Rubbing happens when there is surface sliding contact inside the machine. In this process, “break in” wear should always be expected. This results in a smoother and low-wearing surface.

Cutting Wear (Abrasive Wear)

Two surfaces penetrating one another will cause this wear. Particles are created from surfaces gouging each other, creating long, ribbon-like chunks.

Rolling Wear (Surface Fatigue)

This type of wear occurs when components of rolling motion come in contact with each other, this is the case in bearing balls. The formation of pits is a result of high load and low-contact surface area contact.

Rolling and Sliding Wear Combined (Surface Fatigue and Abrasive Wear)

This combination of wear modes is caused by fatigue and scuffing. This wear combination, along with the effects of lubricant contaminants, can create a complex combination of wear debris. This wear combination is commonly associated with gear systems. As an example, the surface contact of gear teeth is a combination of rolling and sliding motion.

Severe Sliding Wear

This type of wear occurs in excessive loads and high speed between contacting surfaces. The area becomes unstable and particles break away when the surface stress is too great. This increases the wear rate.

Chemical/ Corrosive Wear

This is also called fretting corrosion, erosion, and stress fatigue. This is the result of improper fluid properties or heavy contamination from water, acid, salt, or bacteria. Lubricants also have rust/corrosion-inhibiting additives to fight the effects of chemical water. Heat is also a major factor in corrosion.

Failed Back-up Bearings

Small rolls with a diameter of around 2 feet perform the actual rolling of the steel to reduce its thickness in a steel rolling machine. These rolls must be re-ground frequently due to the importance of surface quality, and their tiny diameter makes them easier to handle. These rolls must be “backed up” by bigger 3-foot-diameter rollers, which are powered and have anti-friction bearings, whereas the back-up rolls have babbitted or plain bearings. Grease or oil spray lubricates the work rollers. A circulating system supplies oil to the backup bearings. The backup rolls are normally kept in the mill for several weeks before they need to be reground. On these rolls, bearing failures are rare.

Work Roll Bearing Failures

The work roll bearings in the mill described previously were anti-friction. At any given moment, there were 40 bearings in the mill, all of which were grease-lubricated. The mill specified the grease’s performance specifications, and each load was checked when it arrived. Each year, between 15 to 20 bearings were lost, mostly on the quicker finishing stands. The losses, which were mostly attributed to age or misdirected water sprays and just rarely to oil, were thought to be normal and difficult to eliminate.

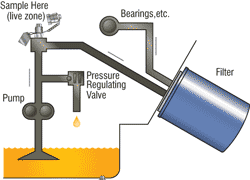

Sampling a pressurized line before the system filter, using a drop tube in the dipstick tube, and obtaining a sample midstream from a drain port while draining the engine are three frequent sampling processes related to engine oil sampling.

pressurized oil sampling

Root Causes of Equipment Failure

Improper Orientation

There are a variety of persons that may come in contact with a piece of equipment on a regular basis and have a substantial impact on its overall performance.

One such group is equipment operators. They often receive in-depth training on suitable operating procedures, basic troubleshooting, and best practices for safe equipment use specific to the machines they’ll be working with. However, there may come a time when an operator is forced to work on a machine for which they were not properly qualified. Other times, events arise that necessitate immediate action by available personnel who may not have the same level of skill as your most experienced operators. The short-term effect of this band-aid solution is not worth the cost in the long run.

One solution to these issues is to make sure you have enough qualified operators on hand to allow for some flexibility and a contingency plan in the event of a staffing shortfall. All of your operators should, if at all feasible, be trained on every piece of equipment, including assets they don’t regularly operate with. Do not allow an operator to operate a piece of equipment that they are not qualified to operate. If you stick to your standard, you do not just eliminate operational errors, but you are also keeping your plant from unnecessary accidents.

Not Performing Preventive Maintenance

Most equipment requires regular maintenance for maximum performance, but when you’re short on employees and overwhelmed, preventative maintenance is often the first thing to go. When things appear to be going smoothly, it’s easy to overlook routine maintenance, and many businesses assume that skilled staff will spot any problems before they become catastrophic.

Preventive maintenance is an important continuing job that should never be neglected. Regular tune-ups will increase the functional life of your equipment, allowing you to get more bang for your buck. Furthermore, preventive maintenance can detect minor issues and provide cost-effective fixes before they become large costly breakdowns. Downtime for routine maintenance and repairs is reduced when you employ effective inventory control tactics to guarantee that you have the proper spare parts in stock for the most common maintenance activities and failures.

Neglecting Equipment Monitoring

Condition-based maintenance refers to routine maintenance that is performed based on the operating condition of a piece of equipment rather than simply following a timetable. When CBM is embedded in your maintenance program, you will have to conduct continuous monitoring. To jumpstart your program, establish a baseline for what an acceptable equipment condition looks like so that tiny changes can be detected and utilized to predict breakdowns and failures. This gives you more time to plan for contingencies and schedule downtime to avoid production interruptions. This form of monitoring, as well as the data gathered in the process, can assist businesses in identifying the reasons for increased machinery stress and adjusting workloads and schedules to reduce the burden on equipment that is showing early signs of impending failure.