Amidst turbine conflict with aging, wear, contamination, and oil scarcity, machine diagnostics through oil analysis program emerges as a strategic solution for early issue detection and maximizing turbine lifespans.

A turbine is a cornerstone of the renewable energy sector, providing clean and sustainable power to millions of households worldwide. Despite continuous advancements in design, lubrication systems, and materials used, maintenance issues persist in turbines. Components are subject to wear and external contamination, leading to a significant decrease in operational efficiency.

Recent global events, including the COVID-19 pandemic and geopolitical tensions, have further compounded challenges in the lubricant industry by limiting the availability of raw materials, such as processed oil. In response to these challenges, programs like machine diagnostics through oil analysis have emerged to enhance early detection of potential failures. By studying degradation modes, oil analysis programs enable owners to proactively address maintenance issues and extend the operational life of turbines.

Strategic Choices: Life Extension, Repowering, or Decommissioning

Turbines' lifespans can be extended by making upgrades, which can result in up to ten more years of production without much risk. They have several choices for maintaining their turbines. Repowering, or replacing old turbines with newer and more efficient ones, sounds appealing, but it involves dealing with authorization challenges and investing more money. If neither of these options works, owners may have to decommission the turbines, even though this comes with immediate financial and operational challenges. Inspecting turbine components thoroughly is crucial for making well-informed decisions, using past performance data to check for any issues and anticipate risks. In this kind of situation, the oil analysis program is not only a sustainable fix but also a preventional cure. It enables owners to foresee events they thought were inevitable and gives a solution to a near-end-of-operational turbines.

Future Trends in Oil Analysis Programs

In the coming years, the wind energy industry will encounter major obstacles as numerous European wind farms near their 20-year milestone. A significant portion of these older assets is located in countries like Germany, Spain, France, the UK, and Italy, presenting challenging decisions regarding extending their lifespan. Despite economic uncertainties, research indicates a consistent increase in operational lifespans, though challenges in electricity market dynamics persist. Innovative approaches, such as enhanced load simulations and inspections, provide solutions to overcome these obstacles.

Conclusion

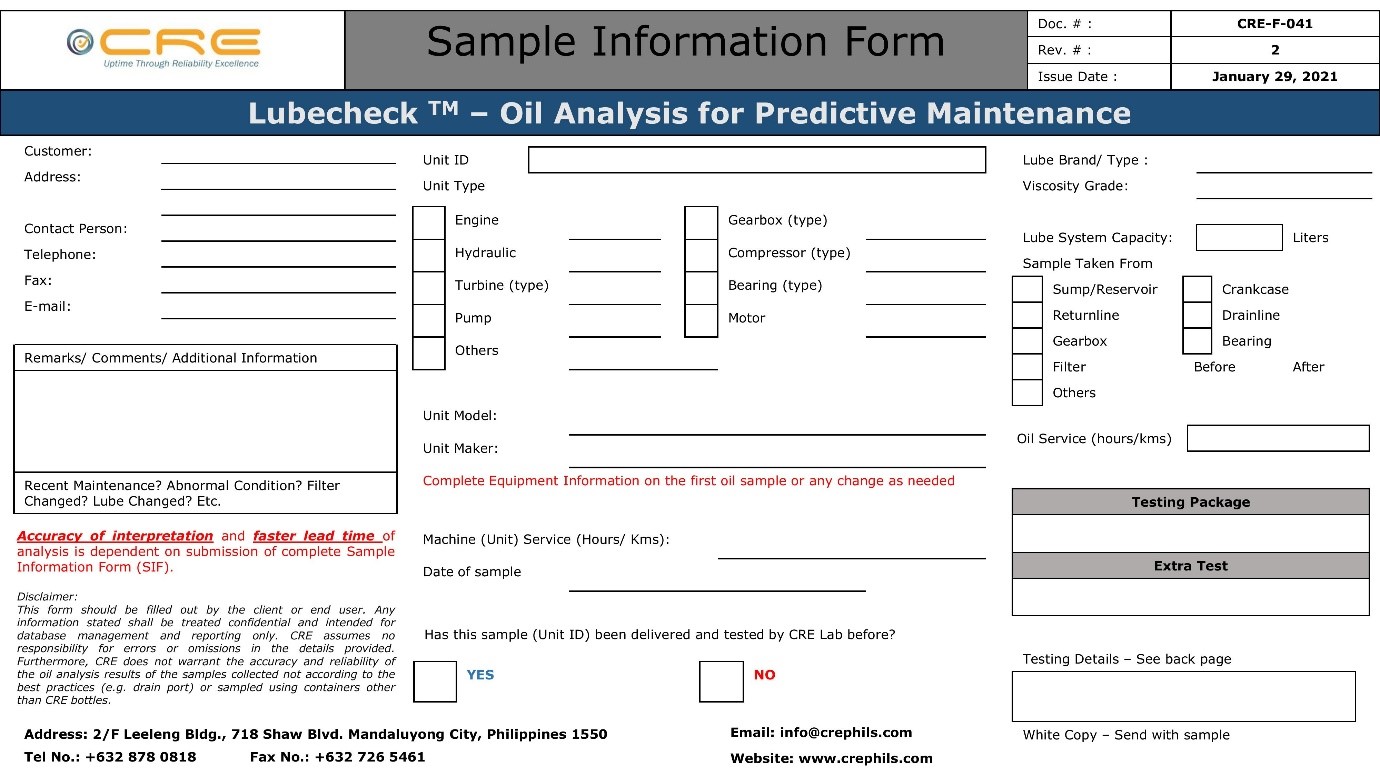

Effectively managing the lifecycle of wind farms requires a thoughtful combination of decisions, technologies, and forward thinking. If you desire to safeguard and solidifyi the foundation of your business, CRE Machine Diagnostics™ Program, stands out as a promising solution, providing early detection of problems and improving turbine lifespans through proactive maintenance. By embracing these innovative methods, the wind energy industry advances its path towards sustainability and leads the transition to renewable energy sources.

Source:

Malaga, A. (n.d.). Utilizing an Oil Condition-Monitoring Program (OCM) to Extend the Life of a Wind Turbine. Machinary Lubrication.

https://www.machinerylubrication.com/Read/32564/utilizing-an-oil-condition-monitoring-program-ocm-to-extend-the-life-of-a-wind-turbine