Oil analysis is a critical tool for evaluating the health and performance of equipment. But before an oil analysis report can be generated, it is essential to complete the Sample Information Form (SIF) wholly and accurately.

In this blog article, we will delve deeper into the significance of the SIF and discuss why it is vital to provide accurate information. We will also provide a quick guide on correctly filling out the SIF.

This article suits equipment maintenance, reliability, and oil analysis professionals. It is particularly relevant to maintenance engineers, reliability managers, and anyone responsible for monitoring and optimizing the performance of industrial machinery.

Crucial Elements

Unit ID and Type

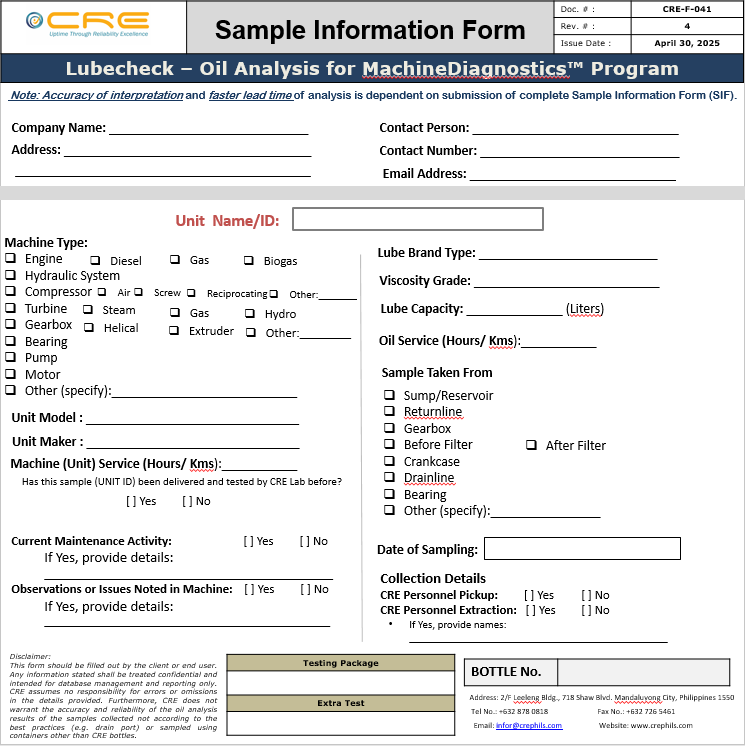

The Unit ID is a critical piece of information on the SIF. It is a unique identifier for the equipment undergoing oil analysis and is vital in accurate identification. But it is essential to note that the current Unit Type tick boxes on the SIF provided by CRE Philippines may be incomplete. Rest assured; our laboratory team is enhancing the form to make it more detailed for our clients.

To fill out the Unit ID section appropriately, follow these guidelines:

- Provide a Unique Identifier: The Unit ID should be a unique alphanumeric code or a combination of numbers and letters assigned to each piece of equipment. Avoid using generic terms or ambiguous descriptions that may lead to confusion or misidentification.

- Consistency in Unit IDs: Assign and record IDs uniformly across similar units to track results, compare trends, and support proactive maintenance planning.

- Avoid Using Serial Numbers: While serial numbers may seem convenient for Unit IDs, they can create challenges when equipment undergoes maintenance or replacement. Serial numbers may change, making historical tracking and analysis difficult. Instead, opt for a separate unique identifier consistent throughout the equipment’s lifespan.

Consider a scenario where a company has many units or equipment of the same type. Without the correct unit ID, machinery may be misidentified, causing report errors and potentially wrong maintenance actions.

Lube Brand

Two other crucial details on the SIF are the lube brand and the sampling date. Providing accurate information on the lube brand is essential for oil analysis. The lube brand refers to the specific manufacturer or supplier of the lubricant used in the equipment. It plays a significant role in oil analysis as different brands may have formulation, additives, and performance characteristics variations. Here’s how to provide the lube brand accurately:

- Specify the Manufacturer: State the name of the lubricant manufacturer or supplier. Avoid using abbreviations or acronyms to ensure clarity and accuracy.

- Include Product Information: Provide details about the specific lubricant product, such as the product name or code. This information helps the laboratory understand the precise formulation and properties of the analyzed lubricant.

Date of Sampling

The date of sampling is essential. It allows the laboratory to assess the oil’s condition over time, tracking any changes or degradation that may have occurred. Time-dependent factors such as oxidation, contamination, and additive depletion can affect the oil’s performance and reliability. By noting the sampling date, the laboratory can compare the analysis results against recommended oil change intervals and identify trends that may state potential issues. Here are some guidelines to correctly fill out the date of sampling:

- Use the Correct Format: Follow a consistent date format, such as dd/mm/yyyy or mm/dd/yyyy, depending on your region or organizational standards. This helps avoid confusion and ensures uniformity in data recording.

- Use the Actual Sampling Date: Enter when the equipment collected the oil sample. It is essential not to estimate or approximate the sampling date as it may lead to inaccurate analysis results and interpretations.

Consequences of Incomplete Details

Filling out the SIF incompletely or inaccurately can have several disadvantages. Incomplete details may result in the laboratory putting the samples on hold, causing delays in receiving the oil analysis reports. Such delays can hinder proactive maintenance actions and exacerbate equipment issues.

Inaccurate or missing information can misinterpret the analysis results. The laboratory relies on the information provided in the SIF to perform a thorough evaluation. Incomplete details may limit the laboratory’s ability to provide accurate recommendations and insights into the equipment’s condition.

Additionally, omitting critical information on the SIF can impede historical tracking and trend analysis. Consistency in filling out the SIF ensures that the laboratory can compare results across many samples from the same equipment, allowing for effective trend monitoring and early detection of abnormal behavior.

General Guide

Here are some general guidelines to consider when filling out the SIF:

- Provide Accurate and Complete Information: Ensure that all fields in the SIF are filled out accurately and completely. Avoid abbreviations, ambiguous terms, or incomplete details that may lead to confusion or misinterpretation.

- Use Clear and Legible Handwriting: Write legibly to prevent errors or misreadings when transcribing the information. Illegible handwriting can lead to mistakes and delays in the analysis process.

- Avoid Guesswork: If you need clarification on any specific information required in the SIF, take the time to gather the correct details. Guesswork or approximations may compromise the accuracy of the analysis results.

- Follow Standardized Units: Use standardized units of measurement to provide consistent and clear information. This helps avoid any misunderstandings or conversions during the analysis process.

- Include More Relevant Information: If more details or specific instructions are related to the equipment or sample, provide them in the designated section or as supplementary notes. This information can provide valuable context to the laboratory team and help interpret the analysis results.

- Review and Verify: Review all the entered information before submitting the completed SIF to ensure accuracy. Double-checking the form reduces the likelihood of errors and gives the laboratory the necessary information for a thorough analysis.

By following these general guidelines, you can contribute to the effectiveness and reliability of the oil analysis process. Accurate and complete information on the SIF enables the laboratory to provide precise analysis reports, allowing for informed maintenance decisions and enhanced equipment performance.

Keep the laboratory updated!

Another crucial tip is to update the laboratory with the latest information on your samples. It is important not to rely on past SIF submissions, especially when using new oil. Communicating and updating the laboratory about any changes or updates in equipment, lubricant, or sampling procedures is essential for accurate and relevant analysis results.

Here’s why keeping the laboratory informed is so important:

- New Oil Considerations: When you introduce new oil into your equipment, it can have different properties, additives, or specifications compared to the previous oil used. Informing the laboratory about this change ensures that they can adjust their analysis and interpretation, considering any variations specific to the new oil.

- Equipment Modifications: If you make any modifications or upgrades to your equipment, such as changing components or adjusting operating parameters, it is crucial to inform the laboratory. These modifications can impact the oil’s performance and degradation patterns, and the laboratory needs to consider these changes for accurate analysis and reporting.

- Sampling Procedures: Any updates or adjustments to your sampling procedures, such as changes in sampling locations, sampling frequency, or sampling techniques, should be communicated to the laboratory. This information helps them interpret the analysis results accurately and make relevant recommendations based on the current sampling practices.

Updating the laboratory with relevant information ensures they have the most up-to-date context for analyzing your samples. This improves the accuracy of the analysis reports and helps you make informed maintenance decisions to optimize the performance and reliability of your equipment.

Remember, oil analysis is an ongoing process, and regular communication with the laboratory ensures they understand your equipment and lubricant conditions. This collaborative approach enhances the effectiveness of the oil analysis program and supports proactive maintenance practices.

Conclusion

Accurate and complete information on the SIF is vital for generating reliable and actionable oil analysis reports. Providing the unit ID, lube brand, sampling date, and other details ensures accurate analysis, proper maintenance decisions, and improved equipment reliability while reducing errors and costs.

Accurately completing the SIF helps companies maximize oil analysis value and optimize equipment performance and longevity.

CRE MachineDiagnostics™ Program

At CRE Philippines, we understand the significance of proper oil analysis and the impact it can have on your maintenance program. We are committed to providing comprehensive support and expertise throughout your oil analysis journey.

With our full support every step of the way, you can start your MachineDiagnostics™ Program through oil analysis. Our program includes a supportive seminar, the Machine Wear Analysis Basic Seminar, which ensures your team is equipped with the best lubrication practices.

Our dedicated support team and certified Lube Analysts provide clear explanations and actionable recommendations for all your report concerns.

Discover how CRE Philippines can help you optimize your equipment performance through oil analysis. Contact us today for the support you need for a successful MachineDiagnostics Program.