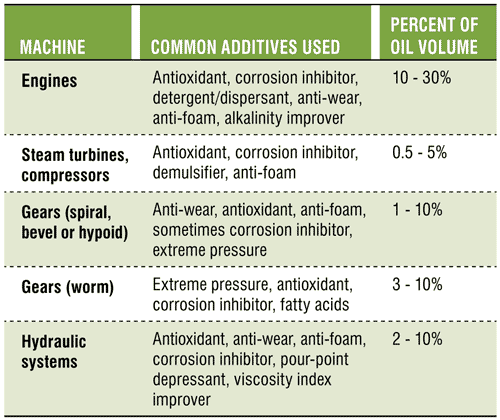

Viscosity is a base oil’s most significant attribute. When establishing baselines for incoming oils, technicians typically check viscosity first. However, lubricants are more than just their viscosity. Understanding the role of additives and their function inside the lubricant is also critical. Additives can either be in the form of organic or inorganic chemicals dissolved or suspended as solids. Depending on their application, they generally vary from 0.1 to 30% of the oil’s total volume.

Functions of Additives

- To improve the properties of present base oils by using antioxidants, corrosion inhibitors, anti-foam agents, and demulsifying agents

- To disguise undesirable base oil properties with pour-point depressants and viscosity index (VI) improvers

- To give base oils new properties using EP additives, detergents, metal deactivators, and tackiness agents

Additives with Polar Properties

Additive polarity determines the attraction of additive molecules toward other polar materials in contact with oil. In other words, “like dissolves like”: polar additives attract other polar substances, such as water, metal surfaces, dirt, sponges, and wood pulp. Meanwhile, wax, Teflon, mineral base stock, and water repellents are examples of non-polar materials.

Types of Lubricant Additives

Formulators add chemical additives to base oils to improve quality, suppress unwanted traits, and introduce new properties. Lubricant additives are expensive and determining the correct percentage or formulation is a science in and of itself.

Lubricant additives come in a variety of shapes and sizes, and formulators choose them based on their ability to perform the required task. Formulators also select them for compatibility with base oils, ease of use with other additives, and low cost. Consequently, turbine oil differs from hydraulic, gear, and engine oils because of the specific additives it contains.

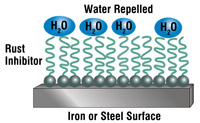

Rust and Corrosion Inhibitors

These chemicals neutralize acids and provide a chemical protective barrier to keep moisture away from metal surfaces, reducing or eliminating internal rust and corrosion. Certain inhibitors are exclusively effective against specific metals. As a result, an oil may contain a range of corrosion inhibitors. Formulators include them in virtually all oils and greases. Another type of corrosion inhibitor is metal deactivators.

Anti-oxidants

The most prevalent cause of oxidation is the attack of oxygen in the air on the base oil’s weakest components. Degradation occurs at all temperatures, but it accelerates at higher temperatures and in the presence of water, wear metals, and other contaminants. As a result, acids and sludge eventually form. Oxidation inhibitors, also known as anti-oxidants, are chemicals that extend oil life. Consequently, these sacrificial additives protect the base oil from oxidizing and are included in nearly all lubricating oils and greases.

Agents that are resistant to wear (AW)

In boundary lubrication, formulators widely use these additives to prevent machine component wear. They’re polar additives that stick to prone-to-friction metal surfaces. When metal-to-metal contact occurs in mixed and boundary lubrication, they react chemically with the metal surfaces. Contact heat activates them, causing the formation of a protective layer that reduces wear. They also prevent the metal from corroding due to oxidation of the base oil. These additives are “used up” as they perform their duties, resulting in increased adhesive wear damage.

Detergents

Detergents serve two purposes. They aid in the cleaning of hot metal components, and the neutralization of acids present in the oil. In motor oils, detergents with alkaline or basic characteristics are widely utilized.

They serve as the foundation for the base number, which reflects an engine oil reserve alkalinity (BN). Calcium and magnesium-based chemical compounds are the most common detergents. In high-temperature applications, metal compounds can produce undesirable residues by forming an ash layer when the oil burns. Therefore, formulators often use a dispersion additive together with a detergent additive.

Dispersants

Dispersants, together with detergents, are added to engine oil to help keep engines clean and free of deposits. Their primary role is to maintain diesel engine soot particles finely distributed or suspended in the oil.

The goal is to keep contaminants suspended in the oil, prevent clumping, reduce damage, and allow removal during an oil change. The majority of dispersants are organic and ash-free. As a result, normal oil analysis has a hard time detecting them. The combination of detergent and dispersant additives neutralizes more acid compounds and suspends more pollutant particles.

Anti-Foaming Agents

Anti-foaming agents weaken the oil bubble walls, allowing foam bubbles to rupture more easily because their compounds have low interfacial tension. They reduce the amount of air-oil contact, which has an indirect effect on oxidation.

Some of these additives are oil-insoluble silicone compounds that are distributed in the lubricating fluid rather than dissolved. In most cases, only a little amount of material is necessary. Excessive use of an anti-foaming component might have the opposite effect, causing more foaming and air entrainment.

Depletion of Oil Additives

- Decomposition or breakdown

- Adsorption of metals, particles, and water on their surfaces

- As a result of settling or filtering, separation occurs.

Mass transfer or physical mobility of the additive is used in adsorption and separation procedures. The longer the remaining additive package is in use, the less effective it is in protecting the equipment. Viscosity rises, sludge collects, corrosive acids assault bearings and metal surfaces, and wear increases as an additive degrades. These issues will reveal themselves much sooner if low-quality oils are utilized.

How to Choose the Right Additives

Aside from a financial standpoint, it is also important to take a look at your OEM Manual to confirm if you are choosing the right lubricant for your asset. Confirm if your lubricant’s additives are compatible with your machine’s metal components, seals, and the existing lubricant in your system. If you are planning to change your oil altogether, conduct thorough flushing of your system. If you have any questions, you may always contact your OEM or partner third-party laboratory. While price is important, it should not be the only determining factor in choosing your lubricant. If you choose to do so, a low-performance lubricant may turn out to be a poor long-term investment, costing you more money and lost productivity in the long run.