The International Council for Machinery Lubrication (ICML) has made a significant stride in the industry of lubrication with the new ICML 55. In an article published by Machinery Lubrication, it was stated that this advanced system now consists of three key documents: ICML 55.0 Overview, ICML 55.1 Requirements, and ICML 55.2 Guideline, offering an in-depth approach to optimizing lubrication processes for mechanical physical assets.

Optimize machinery performance with effective lubrication. Learn how proper lubrication procedure increases efficiency, extends equipment lifespan, reduces downtime and costs, improves reliability and safety, protects the environment, and ensures compliance.

Explore advance innovations in Root Cause and Failure Analysis for improved lubrication practices. Learn how advanced data analytics, IoT integration, and AI-driven insights enhance machinery reliability and efficiency.

Explore the crucial role of a Machinery Lubrication Engineer in maintaining industrial machinery efficiency and reliability. Learn about their key responsibilities, from selecting lubricants to managing compliance, and discover our expert training programs to enhance your skills.

Learn how to design an effective lubrication program to optimize machinery performance and reliability. Explore essential components, strategies, and best practices to enhance operational efficiency and longevity.

Want to boost your machinery's longevity and streamline operations? Discover how Noria's LubePM and LOP PM can enhance your lubrication management for improved operational efficiency.

Discover the essentials of a world-class lubrication program and learn how structured methodologies and advanced technologies enhance machinery efficiency and reliability.

Learn the essential steps for effective oil flushing to maintain machinery performance and longevity. Our guide covers preparation, inspection, flushing, and more. Optimize your maintenance practices with these best practices for reliable and efficient equipment operation.

Workforce development is vital for the industrial maintenance and reliability industry. Discover how investing in skilled training enhances operational efficiency, adapts to technological changes, and addresses the skills gap. Explore strategies to overcome challenges and the importance of ongoing education and mentorship.

Are you tired of dealing with constant breakdowns and skyrocketing repair costs? Curious about how to maximize efficiency and extend the lifespan of your equipment? Join us as we explore the power of Noria's Lubrication Program Development in revolutionizing your maintenance strategy.

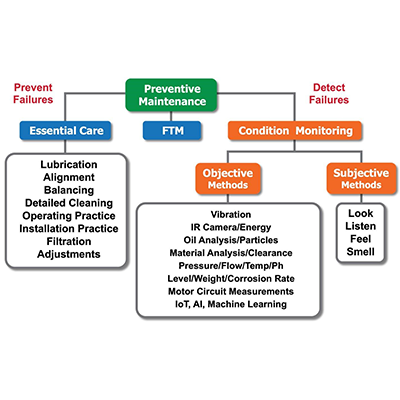

Maximize equipment uptime and minimize costs with our comprehensive guide to cost-effective preventive maintenance strategies. Discover key elements such as data-driven insights, risk-based prioritization, and condition monitoring technologies to enhance reliability and efficiency in your manufacturing operations.

In the dynamic world of industrial operations, maintaining equipment reliability is paramount. For any asset-intensive industry, downtime can be costly, both in terms of lost productivity and repair expenses. That's where maintenance strategies come into play.

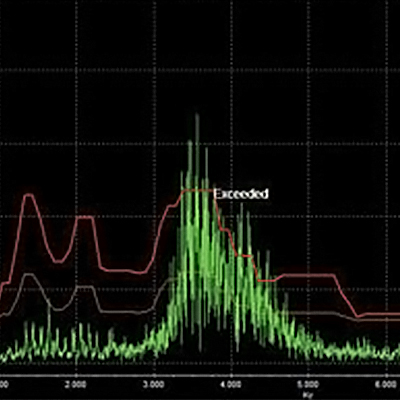

This in-depth guide will teach you how to understand oil analysis results. Gain insights on oil condition, contaminants, wear metals, and additives to maintain machinery performance.

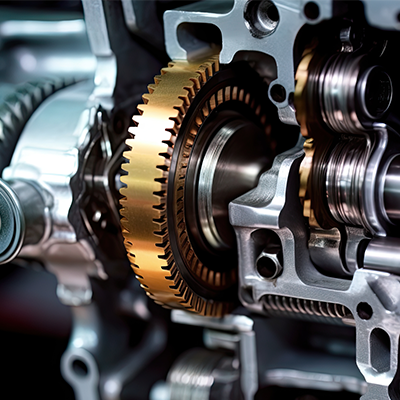

When it comes to maintenance in industrial settings, few things are as critical as proper lubrication management. Lubricants play a pivotal role in keeping machinery running smoothly, reducing friction, preventing wear and tear, and ultimately extending the lifespan of equipment.

Discover how to reduce equipment downtime by 50% with preventive maintenance optimization and AI. Learn about the benefits of proactive maintenance strategies and how they enhance productivity, reliability, and cost savings.

Learn how maintenance can be optimized through advanced oil analysis techniques such as particle counting. Explore the significance of incorporating particle counting into maintenance practices to enhance equipment performance and longevity. Are you leveraging innovative maintenance strategies to maximize the efficiency of your machinery?

Enhance your machinery's performance and reliability with our blog on Oil and Vibration Analysis. Discover how integrating vibration and oil analysis can optimize your maintenance strategy, ensuring the longevity and optimal performance of your industrial equipment.

Proper lubrication is crucial in industrial machinery for precision and efficiency. It ensures the smooth operation and longevity of critical components. This article will explore the ins and outs of machine lubrication.

Unlock the power of Machinery Criticality Analysis to boost reliability and minimize downtime. Explore key concepts like the Reliability-Risk Connection and Overall Machine Criticality.

Common lube room mistakes can lead to extra costs, unplanned downtime, and risks. Optimizing lubrication practices could help prevent these problems and ensure efficiency and cost-effectiveness. Explore how to address issues like storage, inspection, training, and handling protocols.