Routine MachineCheck

-

EngineCheck™ 804Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check

EngineCheck™ 804Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check -

GearCheck™ 804Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check

GearCheck™ 804Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check -

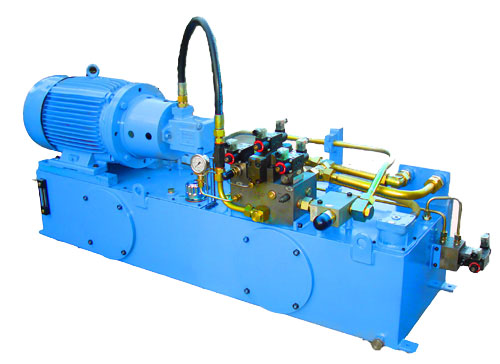

PumpCheck™ 804Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check

PumpCheck™ 804Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check -

CompressorCheck™ 804Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check

CompressorCheck™ 804Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check -

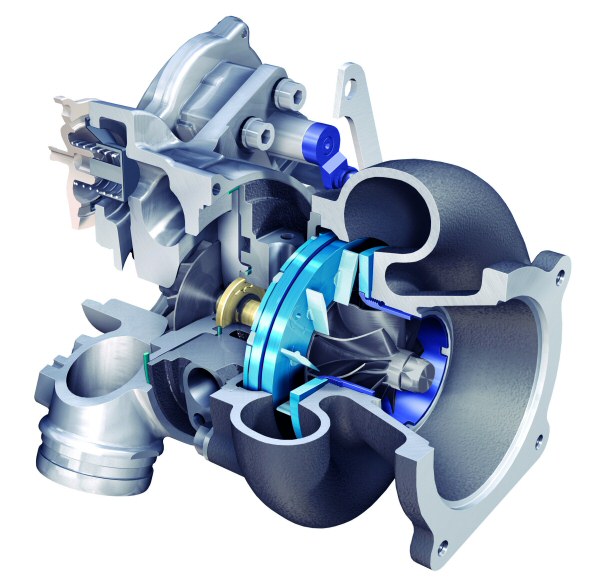

TurbineCheck™ 813

Condition Test: Oil, Contamination, Wear Special Test: Double Wear Check, Particle Count results in NAS 1638 & ISO 4406, Varnish & Sludge Potential Index (VsPITM)

-

NewOilCheck™

NewOilCheck™ -

CoolantCheck™

-

HeatTransferCheck™

-

AviationCheck™

Premium MachineCheck

-

EngineCheck™ 894Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check, Particle Count results in NAS 1638 & ISO 4406

EngineCheck™ 894Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check, Particle Count results in NAS 1638 & ISO 4406 -

TurbineCheck™ 814Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check, Particle Count results in NAS 1638 & ISO 4406, Remaining Useful Life Evaluation Routine (RULERTM), Varnish & Sludge Potential Index (VsPITM)

-

PumpCheck™ 894Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check, Particle Count results in NAS 1638 & ISO 4406

PumpCheck™ 894Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check, Particle Count results in NAS 1638 & ISO 4406 -

CompressorCheck™ 894Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check, Particle Count results in NAS 1638 & ISO 4406

CompressorCheck™ 894Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check, Particle Count results in NAS 1638 & ISO 4406 -

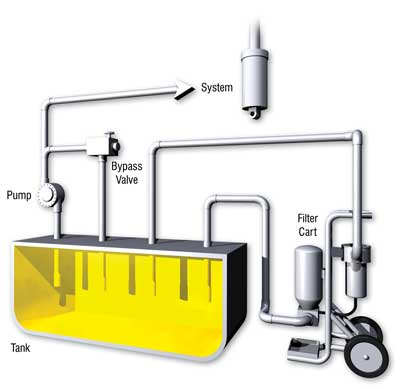

HydraulicCheck™ 894Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check, Particle Count results in NAS 1638 & ISO 4406

HydraulicCheck™ 894Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check, Particle Count results in NAS 1638 & ISO 4406 -

GearCheck™ 884Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check, Ferrographic Analysis

-

GearCheck™ 832

GearCheck™ 832Condition Test: Oil Condition, Wear Condition, Contamination Condition

Special Test: Grease Mixing, Ferrographic Analysis

Advanced MachineCheck

-

CompressorCheck™ 813Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check, Particle Count results in NAS 1638 & ISO 4406, Varnish & Sludge Potential Index (VsPITM)

CompressorCheck™ 813Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check, Particle Count results in NAS 1638 & ISO 4406, Varnish & Sludge Potential Index (VsPITM) -

HydraulicCheck™ 813Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check, Particle Count results in NAS 1638 & ISO 4406, Varnish & Sludge Potential Index (VsPITM)

HydraulicCheck™ 813Condition Test: Oil, Contamination, WearSpecial Test: Double Wear Check, Particle Count results in NAS 1638 & ISO 4406, Varnish & Sludge Potential Index (VsPITM) -

TurbineCheck™ 815

Please see CRE Special Test Parameters.