Experience the only AI-powered predictive maintenance program in the Philippines that gives you a true 360-degree view of your machines—combining expert-led oil and vibration analysis with intelligent diagnostics to predict, prevent, and optimize.

See the Future of Your Equipment Before It Breaks with MachineForesight360™

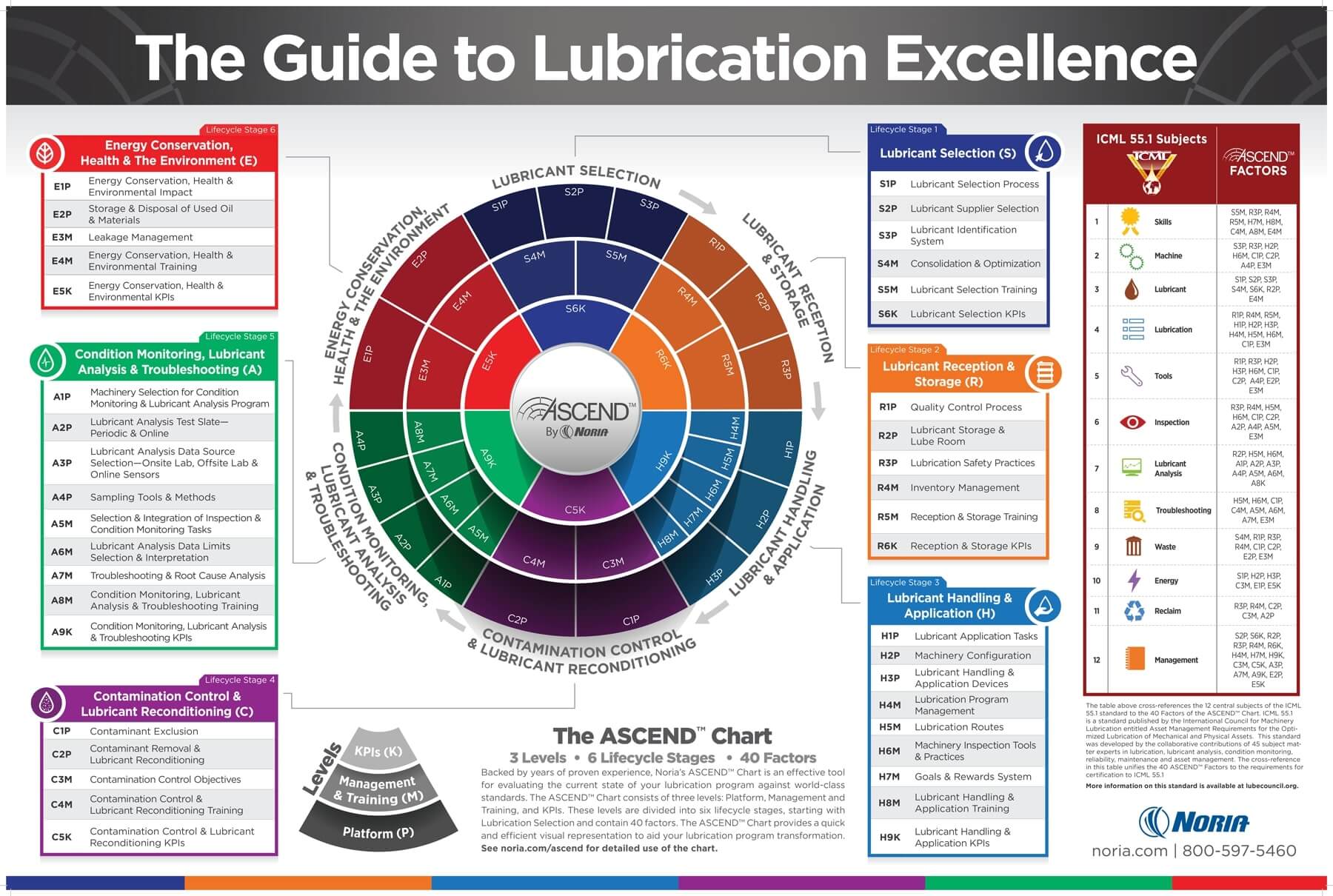

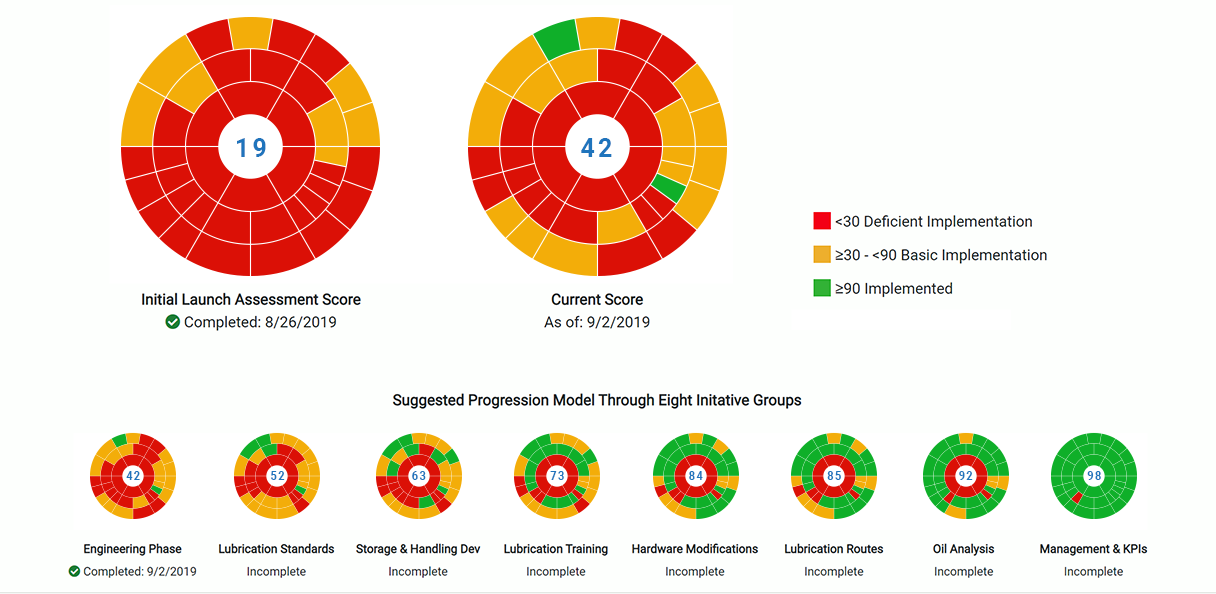

Beyond Routine Maintenance. Beyond Guesswork.MachineForesight360™ is CRE Philippines' proprietary, AI-enhanced diagnostic program designed to provide real-time insights, early warning systems, and failure prevention for industrial machinery. Unlike traditional diagnostics, MachineForesight360™ gives your team foresight—not just snapshots—by continuously analyzing vibration signals, lubricant condition, and operational trends.

✅ No Unscheduled Downtime: We work around your schedule—no shutdowns required for assessments.

🛅 Multi-Dimensional Diagnostics: Combine oil, vibration, and environmental data into one clear picture.

🚨 Early Warning System: Catch critical issues before they escalate—with real-time alerts and alarms.

🤝 Expert-Guided Maintenance: Our certified oil and vibration analysts are here to support your team.

☁️ Cloud & AI-Driven: Access insights from anywhere, anytime. Scalable, secure, and smart.

Seamless Integration with Your Maintenance Workflow

MachineForesight360™ is designed to integrate effortlessly into your existing operations. Whether you’re a manufacturing plant, energy facility, or heavy industry operator, our system adapts to your tools, your team, and your needs.

Optional Enhancements:

📶 Remote Monitoring Integration – Continuous streaming with alarm notifications

🧠 Machine Learning Models – Predictive trend modeling with automated analysis

🧪 Combined Modal + Vibration Testing – For large machine dynamics

👩🏫 Training Workshops – Free for 4 hours; extra sessions available upon request