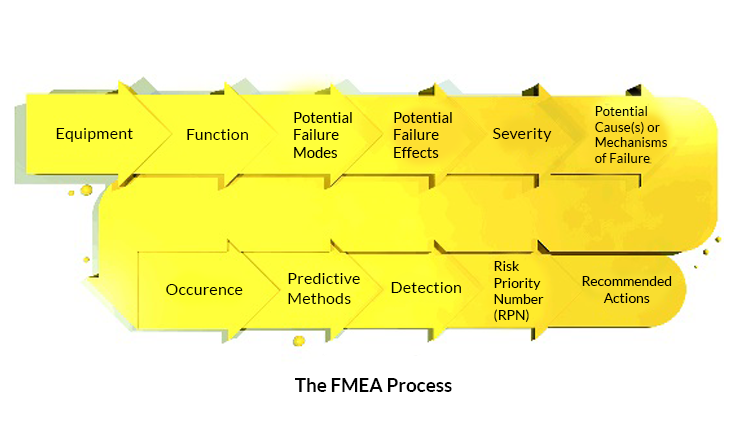

For more than 60 years, failure mode and effects analysis (FMEA) has been used to determine the cause and impact of equipment and process failures to improve the reliability of equipment and systems. FMEA is a systematic procedure for identifying probable failure modes and effects before failures occur.

Failure Mode and Effects Analysis

Failures Modes signify the various ways in which something could fail. Any faults or defects, especially those that affect the client, are considered failures, and they might be theoretical or actual. On the other hand, Effects Analysis refers to the study of the ramifications of those failures.

Failures are ranked according to the severity of their repercussions, the frequency with which they occur, and the ease with which they may be identified. The goal of FMEA is to take steps to eliminate or reduce failures, beginning with the most critical. Manufacturing and process organizations are aggressively introducing reliability-centered maintenance (RCM) programs in an attempt to rationalize and optimize maintenance processes. The RCM process ensures that maintenance operations and reliability targets are closely connected by guiding resource allocation decisions. As a result, for optimal operation, those reliability goals are matched with organizational goals such as maximizing profit and shareholder equity, ensuring safety, limiting environmental effects, and so on.

FMEA differs from failure root cause analysis (FRCA) because FRCA is used to examine failures after they have occurred. Nevertheless, FRCA and FMEA work hand-in-hand. FRCA prepares the ground for the FMEA, which results in a strategy for deploying necessary maintenance measures. Because failure happens before FRCA can be performed, it is too costly for critical systems to be employed alone. That is why it is more practicable to forecast likely failure modes and sequences in advance or simulate failures in an experimental setting instead of letting a failure occur before a maintenance plan has been implemented

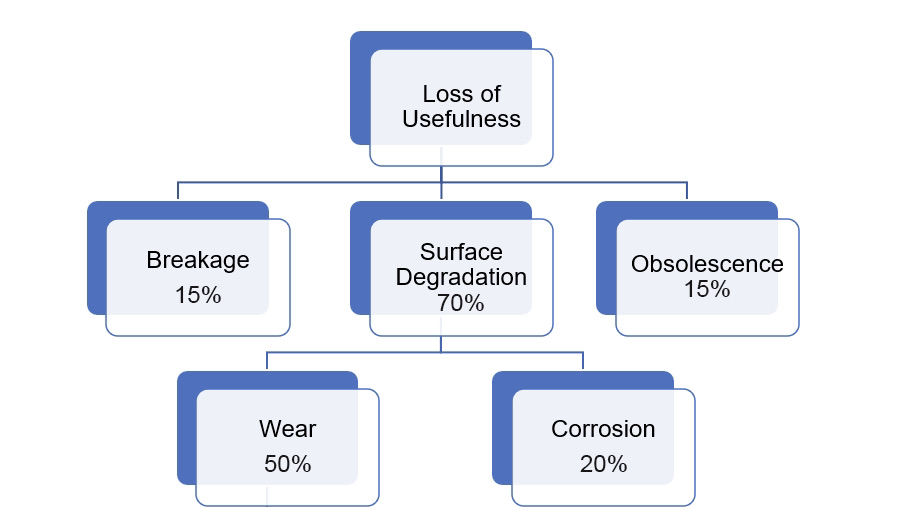

Global Failure Modes

1. Breakage

2. Obsolescence

3. Surface Degradation

Based on the graph, 70% of the issues that lead to the loss of usefulness of lubricated equipment are due to surface degradation which can be a great opportunity and a great choice as your starting point for your maintenance improvement plans.

Causes of Surface Degradation

• Corrosive Wear

• Surface Fatigue

• Abrasive Wear

• Adhesive Wear

• Thermal Degradation

Corrosive Wear

The majority of surface corrosion is caused by acidic lubricants. Lubricants become acidic as a result of oxidation. Acidity in lubricants is quantified by measuring the total acid number (TAN) of used oil samples which is compared against the TAN of the fresh lubricant. Internal deposits of gums, varnish, and sludge are also caused by oxidation reactions in the lubricant. Surface corrosion as a result of an additive reaction is uncommon. Additive interactions with copper or silver surfaces are the most common sources. Elemental oil analysis can easily detect this issue.

Surface Fatigue

Components do not last forever. Over-speed or overload of the equipment, especially in the case of bearings and gear surfaces, causes premature surface fatigue. Doubling the speed reduces bearing life by about 50%, and doubling the load reduces bearing life by about 87.5 percent. Because surface fatigue is easily camouflaged by catastrophic adhesive wear or catastrophic abrasive wear caused by big chunk spalling, it is particularly difficult to detect in operating systems.

The detection of wear particles may require partial disassembly and bore scoping by a professional technician or direct reading ferrographic analysis of wear particles. Definite confirmatory inspection is done by disassembling the machine and inspecting the component with microscope devices.

Abrasive Wear

These particles are a mix of wear particles from adhesive wear, dirt, and other abrasive particles that may come from different sources from the surrounding environment which can be easily addressed by regularly checking seals and installing an offline filtration system.

To remove pollutants introduced during production and assembly, new machinery and systems must be cleansed. Also, if you want clean and new lubricants, you must specify the ISO cleanliness requirements for new lubricants to set the standard and you must employ filtering systems to ensure that the standard is met before moving the new lube from its container into the reservoir or sump.

Adhesive Wear

The wear of adhesives is caused by metal-to-metal contact. Due to a lack of or loss of the lubricating coating, surface asperities contacting under load while sliding will create heat, friction, and wear. Adhesive wear can range from minor running-in wear caused by a poorly specified break-in oil to damage caused by an entire lack of lubrication on surfaces welded together.

The viscosity of lubricating fluids is its most significant physical characteristic. The viscosity of a fluid is a measurement of its resistance to flow as a function of load, temperature, and speed. The ability of the lubricant to reach the contact zone of the moving surfaces and remain in the contact zone for the required period under the given load to avoid metal to metal contact is determined by its viscosity.

Thermal Degradation

Molecule shearing, reduced viscosity, and polymerization are all caused by the high heat and cracking involved. When molecules shear, they can either volatilize, leaving no deposits, or condense, causing dehydrogenation and depositing lacquer and coke. Reduced viscosity is the major indicator of thermal degradation when compared to increased viscosity during oxidation.

Lubrication FMEA Process

The phrase "lubrication failure" must be defined more accurately in the FMEA process to achieve its full benefits, due to the crucial nature of the lubricant and the frequency with which mechanical failure is connected to the lubricating system. To start with the process, register to download Lube FMEA Worksheet.

1. Define the functions of the lubricant that is being investigated.

2. Determine the lubrication-specific failure mechanism that could obstruct the machine's functional functioning.

3. For each machine, make an X in the boxes where the Lubrication Function and Lubrication Failure Mechanism intersect. Lubricant degradation, for example, can't affect power and work transmission in a bearing oil system because that function is exclusive to hydraulic machines.

4. Identify the precise lubrication-related failures that are the underlying root causes of failure modes that lead to a loss of system functioning in the Causes, or Failure Mechanisms section. For example, the lubrication failure mechanism "particle contamination induced loss of power and work transfer functionality" might result in a loss of, or degraded, hydraulic system performance, preventing the machine from stamping, molding, and other operations.

5. Complete the FMEA process as described previously.

A new degree of accuracy in maintenance and control over leading root causes of failure can be obtained by removing the habit of carelessly lumping technically unrelated failures under the category of "lubrication failure." For more accurate identification of lubrication failures after, a similar technique may be used in the deductive FRCA process.

If you want to learn more about Failure Mode Effects Analysis due to lubrication issues, CRE Philippines offers a Machinery Lubrication Engineer (MLE) course. Go beyond the standard lubricant and lubrication topics and take a comprehensive approach to planning, executing, and maintaining a world-class lubrication program. This Online Live training will be conducted on October 25-30 2021.

Source: machinerylubrication.com