With expensive lubricants and the requirement for machines to operate harder and quicker, high-performance lubricants are in high demand. Oftentimes our expectation that the lubricants we ordered should satisfy the viscosity, base oil, performance characteristics, and the contaminant cleanliness objectives that were marketed at the time of purchase. However, believing that all the lubricants you buy always satisfy the requirements of your machines is a common pitfall for maintenance personnel.

The Importance of Quality Control Process

The process of formulating, blending, to delivering lubricants is a lengthy process. There are so many stages that could expose them to contaminants. Another factor is the incompatibility of oils which could also be a source of cross-contamination. Because most lubricants are made up of two to three different base stocks, a simple mix-up of base oils in the blend plant might mean trouble right away. By now, you should have a good grasp on the many challenges that you may have to contend with before your lubricant arrives at your warehouse. When the point-of-fill into drums is farther down the supply line, the effects easily pile up and get amplified.

Lubrication Excellence

In identifying the beginning point on the road to lubrication excellence, a comparison of present operations to lubrication best practices is always necessary. Once the gap has been identified, an optimal road map must be developed to guarantee that resources, effort, and time are spent on activities that provide the best return on investment.

Based on lubricant lifecycle rationale, as well as the impact of improvements on machine reliability and other organizational objectives, categorization is required. Assessing progress, keeping the transformation plan on track, identifying deviations, and ensuring that the benefits are for the long haul once the process has begun are all crucial.

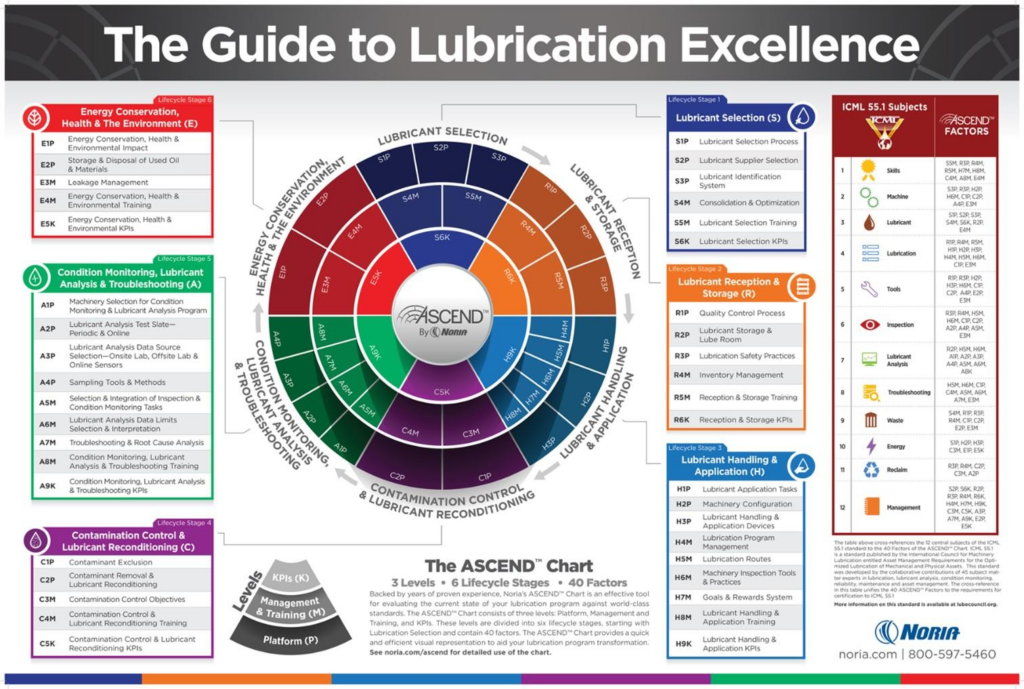

Noria’s Ascend™ has been developed as a step forward from the traditional radar chart which has been used to evaluate the lubricating process for years. It is aligned with the standard set by ICML 55.1 which is also aligned to ISO 55000. ICML 55.1 defines the requirements for your optimized lubrication practices for mechanical machinery.

Lubrication Lifecycle Stages

Selection, reception, application, management, analysis, and disposal are the six lifecycle stages used by Ascend™ in the following order: selection, reception, application, management, analysis, and disposal. It considers the significance of each of these steps as well as the impact they have on lubricant quality, machine reliability, and asset management.

Ascend™ highlights the importance of selecting the right lubricant for the task, with performance matched to the machine’s requirements and operating conditions. But it doesn’t end there. It must also arrive in excellent operating order, be properly kept, and be applied to the machinery at the right place and frequency.

Precision lubrication also entails applying the right amount of lubricant with the right instruments by someone who has the necessary expertise and abilities. Finally, lubricant contamination control and the use of lubricant analysis as a gauge for the status of lubrication and overall machine health are critical.

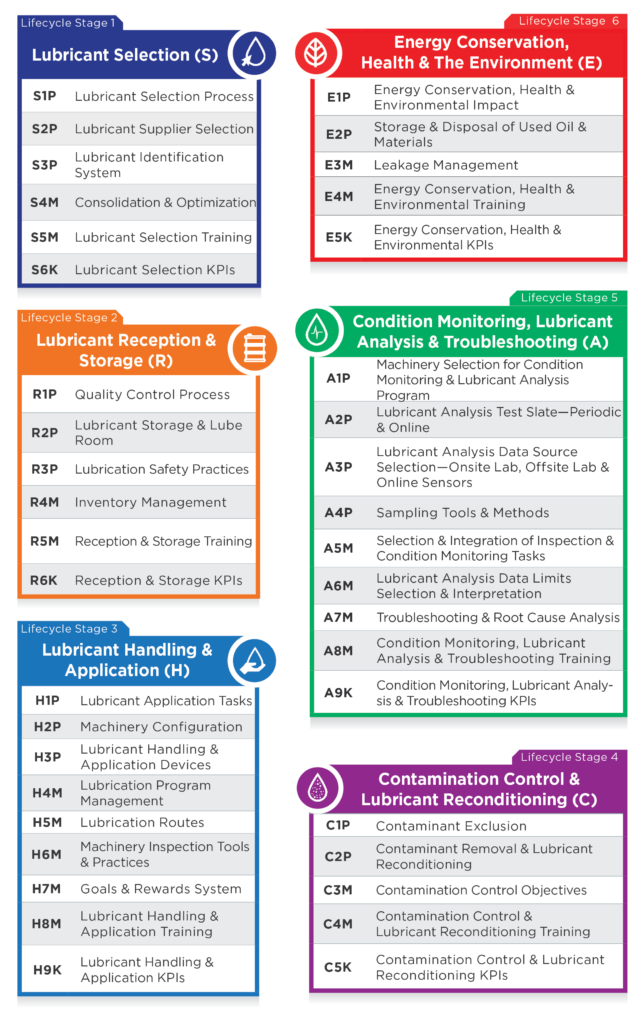

The life cycle stages are shown as angular wedges on the Ascend chart:

- Lubricant selection (S)

- Lubricant reception and storage (R)

- Lubricant handling and application (H)

- Contamination control and lubricant reconditioning (C)

- Condition monitoring, lubricant analysis, and troubleshooting (A)

- Energy conservation, health and the environment (E)

Management Levels

Lubrication activities across the lifecycle of the lubrication process are categorized into 40 Factors in the Ascend methodology™. Each of these elements is linked to one or more of the lubrication plan’s 12 areas.

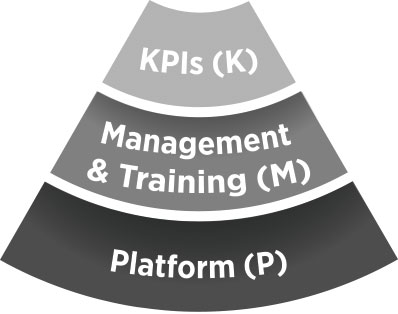

It should be emphasized, however, that these 40 elements do not all carry equal weight when it comes to the creation and implementation of the lubrication plan. The elements are organized into three tiers to accentuate and clarify these disparities:

- Platform (P)

- Management and Training (M)

- Performance Indicators (K)

Platform factors are the program’s foundation and are aimed at reducing risks, ensuring performance, and maintaining the program’s long-term viability. Meanwhile, Management and training factors enable the provision of the needed resources. Staff education and skill development activities are sat this level. These are the lubricating activities that all platform factors support daily. Key Performance Indicators (KPIs) level provides for the monitoring of the efficiency and efficacy of lubrication program activities, as well as continual improvement.

Each factor in the chart is represented by an alphanumeric code made up of three digits: the first represents the Lubrication Lifecycle Stage, the second is the stage’s factor number, and the third represents the Management level.

Using Ascend™ to Track Improvement

The Ascend™ method employs the Six Sigma methodology to help determine your lubrication program’s level of maturity. This is compared against the Optimum Reference State (ORS) which is set by ICML 55.1. Interviews and measurements are done to conduct the assessment which will be used to compute your level of compliance.

Execution Plan

Based on the maturity of the elements at various levels, the Ascend™ Chart provides an ideal way of implementation. A score of less than 30% warrants a red color (the lowest level of maturity), 30% to 90% a yellow color, while 90% or better (the highest level of maturity) is a green color. This allows you to focus on the areas that need your immediate attention. Ascend™ is an ideal tool for constructing your transformational road map by deciding which aspects should be handled first based on lifecycle logic, relevance to business objectives, and plant reliability.