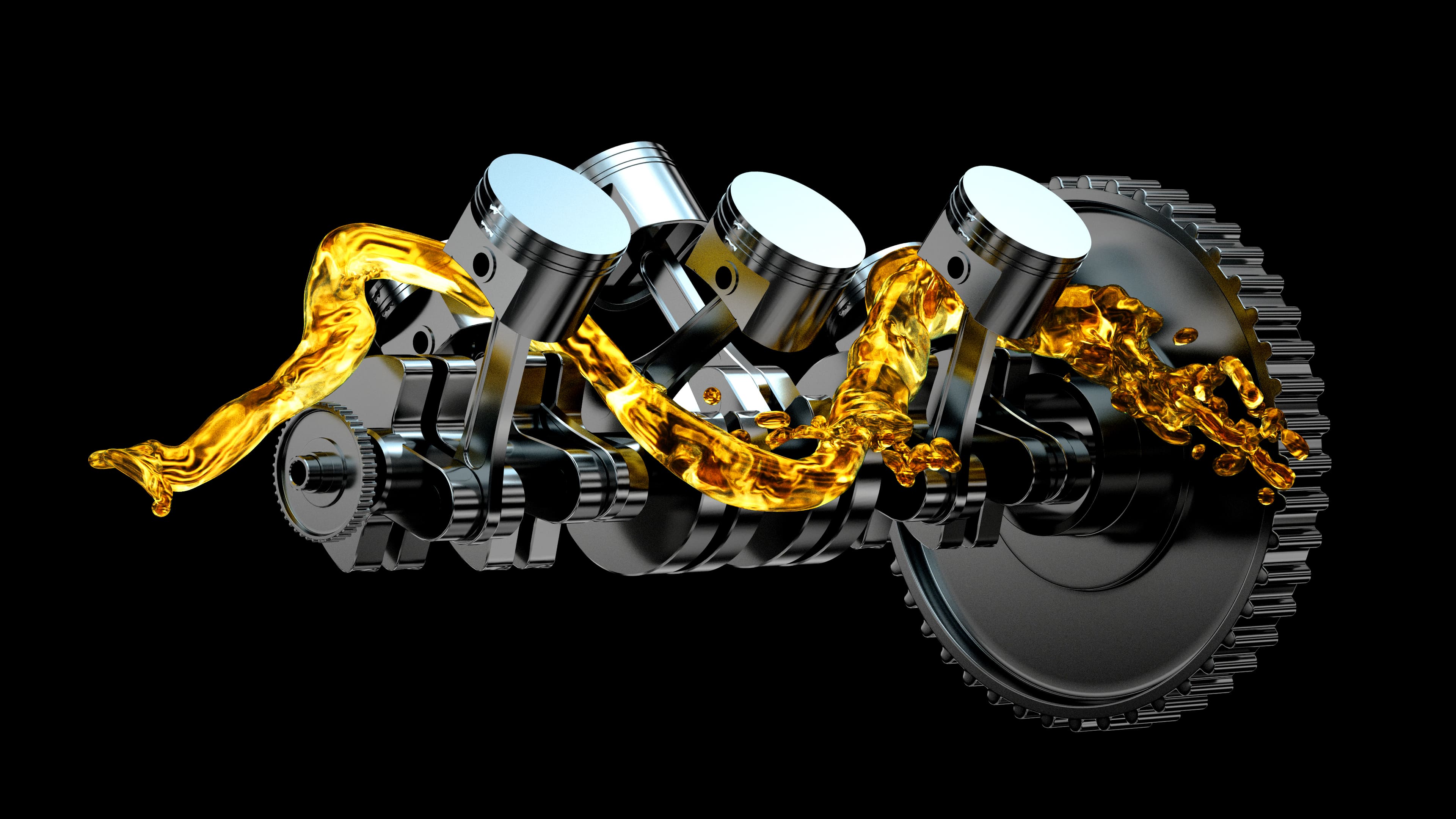

Lubrication is critical for machinery durability and performance, impacting functioning, composition, terminology, application method, longevity, and prioritizing quality over cost. Sink deeper into knowledge about this powerful substance and gain confidence in selecting the most ideal lubricant moving forward.

Navigating the Landscape of Lubricants

Lubrication may seem like a mundane aspect of equipment maintenance, but it's a crucial component that significantly impacts the lifespan and performance of machinery. With numerous factors to consider, selecting the right lubricant can be daunting. However, understanding key details can simplify the process and ensure effective equipment lubrication. Let's delve into six critical factors to consider when choosing a lubricant:

1. Functionality: The main purposes of lubricants in machinery are to control temperature, decrease wear and corrosion, and reduce friction. It's critical to evaluate the unique difficulties your equipment encounters, such as high pressure, severe temperatures, or contact with corrosives, and select a lubricant designed to meet those needs.

2. Composition: Different additives are added to lubricants to improve their performance in particular applications. Knowing what makes lubricants, whether they are oils or greases, is essential. For example, greases are oils with thickeners added, and the kind of thickener used affects the oils' capacity to withstand heat, water, and shear.

3. Terminology: To make wise selections, familiarize yourself with the jargon related to lubrication. When choosing the proper lubricant for your machinery, the following terms might be helpful:

Viscosity: This refers to how thick or hard the oil or grease is to flow. Higher viscosity equals higher flow resistance.

Kinematic viscosity: A simple pour test can provide a visual representation of viscosity. Lube professionals can demonstrate kinematic viscosity on the shop floor since it is simple to execute and takes minimal time.

Weight also affects how viscous an oil is and how easily it flows at a given temperature.

NLGI consistency: This determines how firm or soft a grease is. The numbers go from 000 (for cooking oil) to 6 (for cheddar cheese).

The phrase "runout" refers to the capacity of grease or oil to endure greater temperatures, which tend to make lubricants less

4. Application Technique: There are differences in the way that lubricants are applied. Take into account how easily accessible the equipment is, and select an application technique that best meets your requirements. Proper application technique guarantees complete lubrication; this includes automated dispensers for difficult-to-reach places and spray lubricants for easily accessible areas.

5. Longevity: Lubricants have a limited shelf life, and if they are not replaced on schedule, machinery breakdowns and downtime may result. Predictive maintenance techniques, keeping an eye on operating temperatures, and following lubrication schedules are essential for prolonging lubricant life and averting expensive malfunctions.

6. Cost vs. Quality: When choosing lubricants, quality must always come first, even though cost is an important consideration. Opting for cheaper options may seem economical initially, but inferior-quality lubricants can lead to increased downtime, machinery damage, and safety hazards, ultimately offsetting any cost savings. Assess the overall impact of lubricant quality on production efficiency, equipment longevity, and maintenance costs to make informed decisions.

Conclusion

In essence, proper lubricant selection is crucial to maintaining mechanical performance and decreasing maintenance costs. By considering factors such as functionality, composition, application technique, and longevity, you can offer lubrication that is tailored to your equipment's needs, paving the way for smooth operations and a longer lifespan. This greatly aligns to the main objective of CRE Philippines' MLT I/MLA I Machinery Lubrication Training. We offer programs that teach best practices for applying, supervising, and implementing lubrication. All the processes from a to z will be covered comprehensively. Backed up with expertise and credible experience in the industry, the trainings will be led by Noria's resource speakers in the Philippines. Develop your capacity to trust your own expertise by reserving a seat now!

Source:

Kowalski, W. (n.d.), 6 Key Factors for Lubricant Selection, Machine Lubrication.

https://www.machinerylubrication.com/Read/31691/lubricant-selection-factors