Lubricants are designed for specific uses but are used in general. Within a single processing plant, there might be hundreds of different types of equipment and manufacturers.

The operation of each equipment type may need specific lubricants.

Each manufacturer of the same equipment type may need a different lubricant. Operators and mechanics are in charge of many aspects of machinery lubrication, but their primary task is to keep processing units running. Understanding lubricants are a secondary priority for operators and mechanics. Thus, avoiding confusion through lubricant selection is critical to preventing costly misapplications.

Bearings

Lubrication of rolling-element and sleeve bearings is based on hydrodynamic and elastohydrodynamic principles. In both cases, the lubricant has low viscosity and contains rust and oxidation (R&O) inhibitors, anti-foam additives, and demulsifiers.

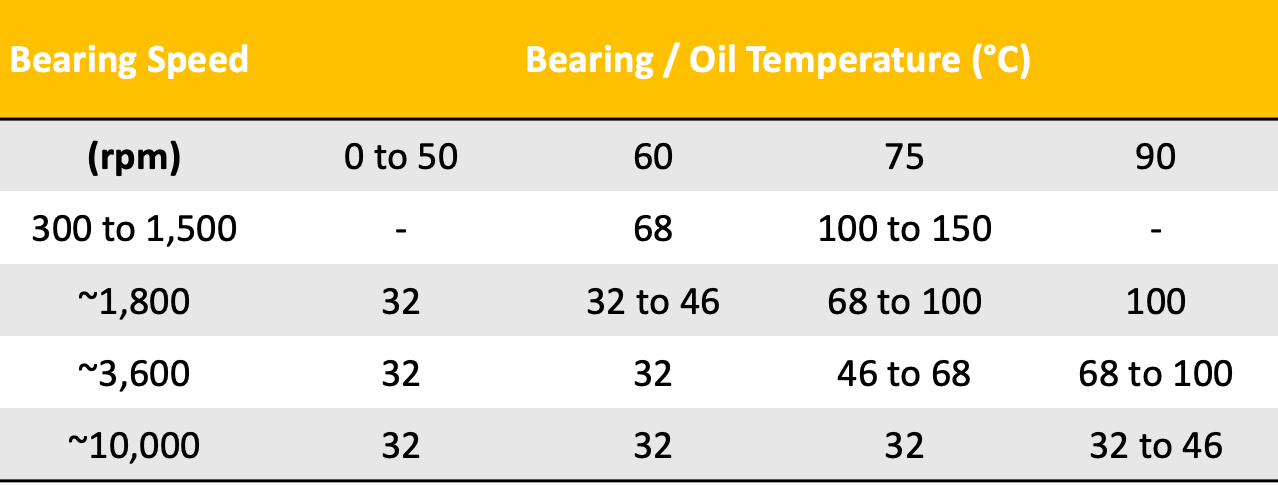

Depending on the range of shaft speeds, a single turbine or R&O oil can be used to lubricate these bearings. Even if the needed oil is one of the most basic lubricants available, it is critical to select the correct one.

Journal Bearing ISO Viscosity Selection (Source: Noria)

Journal Bearing ISO Viscosity Selection (Source: Noria)

Pump Bearing

Centrifugal pump shaft bearings are lubricated using ISO viscosity grade (VG) 32, 46, or 68 R&O oils. Oil-mist lubricating systems are used to distribute lubricant to centrifugal pump bearings. Due to the small orifices and liquid state phase changes, a diester-based fluid is ideal for use in an oil-mist lubrication system.

Gearbox

Parallel-shaft gearboxes can generally be lubricated with one fluid type, ISO VG 220 rated. IS0 VG 460 worm gear or synthetic lubricant is often used to lubricate industrial right-angle gears.

Since right-angle gearboxes may contain brass and steel gears, it is a good idea to default to synthetic gear oil because most mineral-based extreme-pressure (EP) gear fluids are aggressive to soft metals. Most gearboxes on tank mixers need lubrication with ISO 150 to 220 non-EP gear fluids. When choosing lubricants for gearboxes, other factors must also be considered.

Reciprocating Compressors

Reciprocating gas compressors use two different lubrication systems: one for crankcase lubrication and one for cylinder lubrication. ISO VG 150 or 220 R&O fluid is necessary for the crankcase. The lubrication regime is hydrodynamic in a reciprocating gas compressor crankcase.

The cylinder lubricant in a reciprocating gas compressor relies on heavy viscosity fluids from ISO 150 to ISO 320 to provide sliding wear protection between the piston rings, slides, and cylinder wall.

Mechanical Seals

A very low-viscosity PAO-based fluid with stable additives at minimum quantities is the appropriate barrier fluid for mechanical seals containing process fluids running at temperatures over 140 degrees F. When a barrier fluid is in continuous service in the heated dead leg of a mechanical seal, it can degrade and leave deposits that lodge in the seal face, thus causing seal wear and leaks.

Lubrication Program Development

CRE Philippines delivers a comprehensive lubrication program established by our partner, Noria, which includes a complete plan that tackles all lubrication-related work processes and procedures, from sale to the needed re-grease amount for each bearing in the plant. With CRE Philippines' experience, cooperation with Noria, and a concentrated team of engineering specialists, you can design and implement a world-class lubrication program that would otherwise take years or decades to complete.

Any choice to establish a new lubrication program must result in a satisfactory return on investment (ROI). Connect with us to discover how much poor lubrication practices cost your company each year and to assist you in implementing a single vision for lubrication excellence.

Source:

Hayes, F. J. (n.d.). The How and Why of Lubricant Selection and Consolidation for Rotating Machinery. MachineryLubrication. Retrieved from https://www.machinerylubrication.com/Read/31578/lubricant-selection-consolidation