Want to boost your machinery’s longevity and streamline operations? Discover how Noria’s LubePM and LOP PM can enhance your lubrication management for improved operational efficiency.

Maintaining operational efficiency in today’s competitive industrial world requires equipping your workforce with the necessary skills and knowledge. Lubrication management is one of the important topics that is frequently disregarded. In addition to increasing equipment dependability, good lubrication techniques help prolong machinery life and lower operating expenses. This blog will walk you through the value of having a strong lubrication program and how to put it into practice in your company.

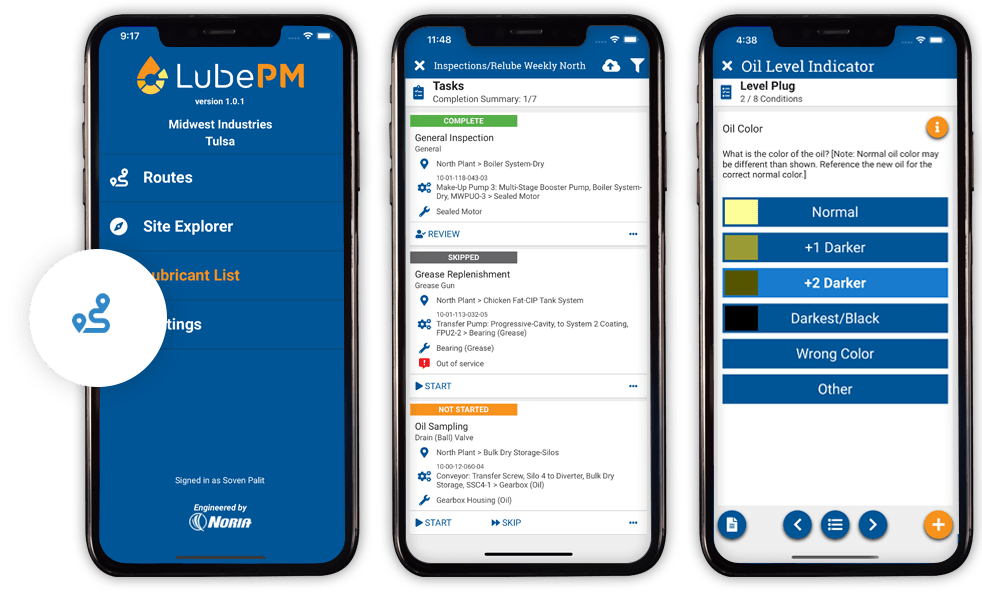

Introducing Noria’s LubePM for Enhanced Lubrication Management

Effective lubrication management is critical to the longevity and operating effectiveness of machinery in the field of industrial maintenance. Noria’s LubePM system emerges as a standout solution, designed to simplify and enhance the process of lubrication management. This innovative system not only makes it easier for teams to perform essential lubrication tasks but also ensures consistency and reliability in maintenance routines.

Our partner, Noria Corporation, has been a beacon of knowledge in the lubrication industry for over 25 years, specializing in training and information dissemination through platforms like Machinery Lubrication magazine. Their latest innovation, LOP PM (Lubrication Program Manager), is designed to streamline and optimize lubrication management across various industries.

Empowering Teams with Easy-to-Use Technology

One of the key features of the LubePM system is its user-friendly interface. Regardless of how frequently an individual engages with the app, its intuitive design allows users to easily resume their tasks without confusion. This ease of use is particularly beneficial for teams that experience frequent changes or additions in personnel.

Training new team members can often be a challenge, especially when relying on traditional methods that depend heavily on experiential knowledge passed down through generations. The LubePM system addresses this challenge by providing standardized lubrication procedures that can be easily accessed through the app. This not only speeds up the training process but also ensures that all team members are equipped with the knowledge to perform their tasks correctly.

Streamlining Processes and Enhancing Reliability

The transition from old-school experiential learning to a more structured, app-based approach has significant advantages. By standardizing procedures, LubePM minimizes the risks associated with human error and variability in performance. It ensures that every member of your team follows the same high standards, leading to more predictable and reliable maintenance outcomes.

For organizations looking to improve their operational efficiency, adopting Noria’s LubePM system could be a game-changing decision. It not only empowers employees by making information readily accessible but also contributes to the overall health and efficiency of machinery through consistent application of best practices in lubrication.

What is LOP PM?

LOP PM stands for Lubrication Program Manager, which is a comprehensive lubrication management system (LMS) intended to simplify the complex aspects of lubrication programs. It integrates both management tasks at the desk level and operational tasks within the plant environment.

Key Features of LPM Software

Dashboard Insights: Upon logging in to LPM, users are greeted with a dashboard displaying vital KPIs essential for monitoring the health of their lubrication program. This includes metrics that track compliance and task completion rates.

Mobile Accessibility: The software extends beyond desktops, offering a mobile app compatible with both Android and Apple devices. This feature allows technicians to access task lists and data analytics directly from the field, enhancing on-site productivity.

Task Routing: LPM excels in task management through its routing features. Technicians can plan their routes efficiently, schedule tasks, and even view them on a calendar to ensure timely execution. This system replaces traditional paper-based methods which are prone to errors and inefficiencies.

Real-Time Updates & Alerts: The platform provides real-time insights about ongoing tasks and highlights any delays or incomplete tasks. It also features an alerts system that notifies managers about abnormalities detected during inspections or routine checks.

Enhancing Compliance with Real-Time Data Capture

LOP PM’s real-time data capture capabilities significantly reduce the risks associated with manual data entry errors. Technicians can flag issues as they arise directly within the app, which then updates the central system accessible by maintenance managers or reliability engineers back in the office.

LOP PM’s real-time data capture capabilities significantly reduce the risks associated with manual data entry errors. Technicians can flag issues as they arise directly within the app, which then updates the central system accessible by maintenance managers or reliability engineers back in the office.

Alerts System for Immediate Actionable Insights

The alerts page within LOP PM highlights incomplete tasks or abnormalities detected during inspections. This feature prompts immediate attention to areas that may require urgent action or adjustments, thereby enhancing machine reliability through timely interventions.

Comprehensive Training & Support Tools

LPM is not just about managing tasks; it also focuses on training personnel through integrated support tools. It offers detailed procedures for each task, ensuring that technicians understand exactly what needs to be done. Additionally, it provides visual aids like photos or videos which can be crucial for new technicians or when tackling complex tasks.

Integration Capabilities with Existing Systems

A significant advantage of using LOP PM is its ability to integrate seamlessly with existing CMMS systems like Maximo or SAP through APIs tailored based on customer needs. This integration facilitates smooth data transfer between systems, ensuring all stakeholders have access to up-to-date information without needing multiple inputs across platforms.

The Future of Lubrication Management with LOP PM

The introduction of technologies like LOP PM by Noria Corporation marks a significant advancement in how industries manage their lubrication programs. By leveraging digital tools such as routing features, real-time data capture via mobile integration, actionable insights from an alerts system, and seamless integration capabilities with existing CMMS systems; companies can expect not only enhanced operational efficiency but also improved machine reliability and longevity.

In conclusion, Noria’s LubePM offers an innovative solution that simplifies complex processes and empowers teams to achieve excellence in machinery maintenance through effective lubrication management. By integrating this technology, companies can expect not only improved operational efficiency but also extended equipment life and reduced downtime.

Contact us today to learn more about Noria’s LubePM system and how it can benefit your operations.