The Philippines is making strides toward enhancing maintenance strategies in reliability-centered maintenance. A critical element in this pursuit is understanding when oil has reached its temperature limit.

Industrial machinery operates under many conditions – from heavy loads and high speeds to continuous operation and intermittent bursts. Manufacturers design lubricants oils and greases with specific formulas to meet the unique demands of each application, considering temperature, speed, load, and oil change intervals.

The ability to withstand temperature fluctuations is critical for machinery ranging from compressors and turbines to engines and gearboxes. Inadequate temperature management can lead to many issues, including reduced machinery lifespan, safety concerns, and decreased efficiency. This blog explores the significance of oil temperature limits in reliability-centered maintenance and explains why and how to monitor them.

The Impact of Temperature on Lubricants

Operating temperature is a fundamental factor influencing a lubricant’s performance and lifespan. Higher working temperatures reduce the lubricant’s service life. This phenomenon occurs due to oxidation, a chemical reaction that transpires when the lubricant interacts with oxygen in the air, leading to changes in its chemistry and lubricating properties.

A well-established principle in the field of lubrication is the Arrhenius Rate Rule. This rule states that the lubricant’s life is halved for every temperature increase of 10 degrees Celsius. The implications of this rule apply to both high-quality and low-quality lubricants, even if the exact durations may differ. Thus, synthetic lubricants, known for their longevity and enhanced temperature resistance when compared to mineral oils, are not immune to the rule of reduced lifespan at elevated temperatures.

Let’s translate these principles into practical terms for the Philippines’ industries and machinery maintenance endeavors. While there is no absolute temperature for a lubricant to operate, high temperatures can create hazardous conditions and cause frequent oil changes. Thus, the question becomes: how do industries and maintenance professionals in the Philippines determine the optimal operating temperature for their machinery?

Monitoring Oil Temperature Limits

To determine if oil has reached its temperature limit, it is crucial to comprehend the processes resulting from temperature-induced degradation. The oxidation of oil not only reduces its lubricating effectiveness but also produces acidic compounds within the lubricant. These acid compounds accumulate as the oxidation process advances during lubricant use.

At a certain point, when the acidity reaches an unacceptable level, it is recommended to change the oil. One of the methods to determine this condition is an acid number test, which measures the acid content in the lubricant.

Moreover, Fourier transform infrared (FTIR) spectroscopy, a powerful analytical tool, can be employed to measure various compounds within the oil, including those that are oxidized. By using FTIR, the extent of oxidation can be quantified.

Experienced maintenance personnel often identify oxidation through visual cues in practical field applications. Oil darkening and changes in odor are associated with oxidation. Yet, these parameters can be somewhat subjective, making determining when the oil has oxidized and requires replacement is challenging.

Effects on Lubricant Additives and Machinery

High temperatures don’t only affect the lubricant; they also impact the additives in the lubricant formula. As the temperature climbs, these additives may degrade, leading to a loss of their beneficial properties. Additionally, the elevated temperature can contribute to the formation of unwanted byproducts within the machinery.

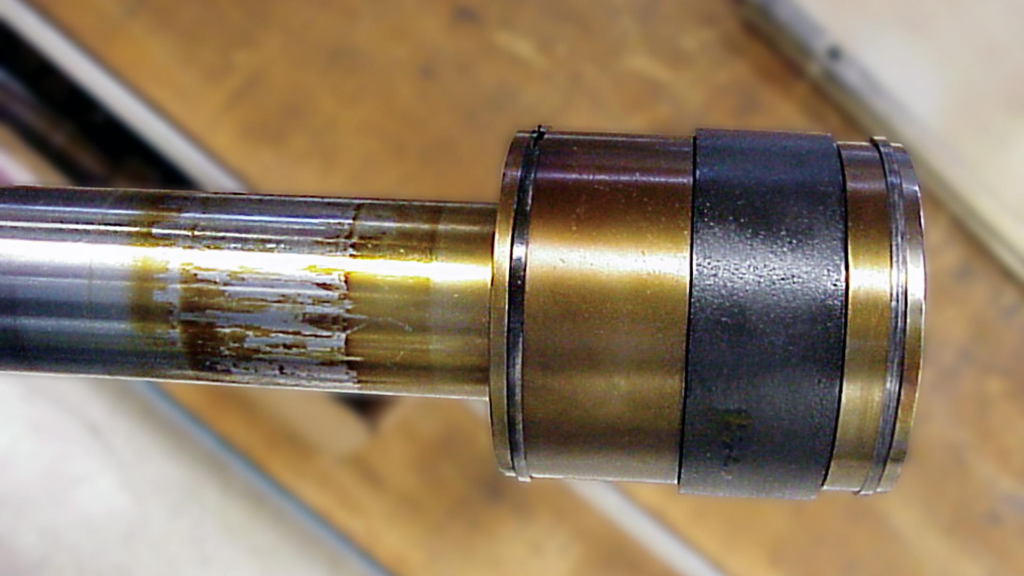

These byproducts, which include sludge, varnish, and lacquers, can affect the performance and lifespan of the machinery. It’s often necessary to conduct internal equipment inspections and use various laboratory tests to identify these effects.

When considering the impact of oil temperature in machinery diagnostics and reliability-centered maintenance, a clear picture emerges: controlling and monitoring oil temperature is vital for maintaining equipment integrity.

In its ongoing journey toward establishing world-class maintenance strategies, the Philippines must consider the importance of oil temperature in achieving reliability targets. Correct oil management within its designated temperature range can lead to longer equipment lifespan, enhanced safety, and increased operational efficiency.

Conclusion

For industries in the Philippines, particularly those engaged in reliability-centered maintenance, the lessons drawn from understanding oil temperature limits have far-reaching implications. The principles discussed in this blog highlight the interplay between temperature and lubricants, underscoring the significance of maintaining machinery within optimal temperature ranges.

To put these principles into practice and embark on a journey towards excellence in machine diagnostics, reliability-centered maintenance, and UPTIME optimization, we invite you to explore CRE Philippines’ MachineDiagnostics™ Program. This comprehensive initiative is a theoretical and concrete pathway toward achieving top-tier maintenance strategies. With MachineDiagnostics™, you can begin your journey toward peak reliability and uptime while ensuring the longevity and safety of your equipment.

Source: https://www.machinerylubrication.com/Read/31466/oil-temperature-limit