Using the correct oil sampling hardware helps ensure you're getting an accurate sample every time. Below we'll talk about the oil sampling equipment you need to take a precise oil sample.

Importance of Proper Oil Sampling

A lubrication professional extracting a representative oil sample is only as good as their instruments, even if they know how to get a suitable oil sample. Without these two things, you'll likely wind up with a non-representative oil sample, which can have detrimental consequences. Using the wrong or inadequate oil sampling hardware, taking oil samples from unsuitable locations, and even mishandling the samples can all lead to an oil sample that doesn't represent the actual condition of your equipment.

Proper oil sampling instruments are also required to avoid exposing the sample and the system to ambient air. The right oil sampling gear may be used to sample oil without opening the bottle. Having a correct-sized and cleaned bottle, a zip-lock sandwich bag, the correct sampling port and valve, and a sampling device like a vacuum pump are all things you'll need to do this.

Below we'll discuss the various oil sampling equipment you'll need to take a representative sample of the oil inside your machinery.

Requirements

Accessories

- Sample extraction tube

- Vacuum pumps

- Oil sample bottles

- Materials

- Opaque plastic

- Polyethylene terephthalate (PET)

- Glass

- Cleanliness

- Clean

- Superclean

- Ultraclean

- Materials

Sampling Ports

Source: Noria

Source: Noria

Two of the most critical aspects of the sampling process are where and how oil samples are collected. But ports are only sometimes where you need them to be.

After unusual circumstances are discovered, installing many ports in strategic areas can assist separate components in helping diagnose the cause of issues. Primary sample ports should be placed where routine samples are taken to get the best fluid and machine condition evaluation. They track oil pollution, wear debris, and the chemical and physical characteristics of the oil. Primary sampling port locations vary, but circulating systems should be located on the return line before the fluid enters the sump or reservoir.

Secondary sampling ports can be placed on a system to isolate components. By inspecting individual parts, you can pinpoint the source of the contamination. When the primary port sample identifies an unusual reading, and you need to study the root cause further, take an oil sample from the secondary port location.

Under typical working circumstances, a suitable sample port is intended to pull samples from the most representative sections of the equipment. This is done using gauge adapters, port adapters, and sample ports with pilot tubes.

Sometimes a machine's design or operation environment necessitates installing a remote oil sampling port through line extensions. It may be necessary to take samples for condition monitoring during runtime conditions. Many machines can't be accessed during normal operating conditions, but yet they may be the most important to sample.

Sample Valves

Sample valves are put at ports on sumps and oil circulating lines for clean and efficient oil sampling. This achieves a controlled, fixed sampling location. Sample valves can aid in the prevention of leaks and unintentional sample contamination. They also don't interfere with the machine's regular operation. As such, samples can be taken during normal operating conditions, improving the sample's quality.

Depending on your system, you might need to use many pieces of oil sampling hardware with the appropriate valve. Consider the following valve options:

- Portable high-pressure valves

- Minimess valves

- Ball valves

- Stauff sampling valve

- Circle-seat control valve

- Fluid line sampling valve

- Parker aerospace sampling valve

- Taylor sampling valve

- Eaton sampling valve

- Checkfluid sampling valves

- Caterpillar sampling valve

Improvements

Over the years, technology and ingenuity have improved upon the designs and availability of oil sampling hardware to make sampling more accessible and more representative of system and fluid conditions. Two of the most notable oil sampling equipment recently introduced are the Ultra Clean Vacuum Device (UCVD) and Luneta's Condition Monitoring Pod (CMP).

The UCVD is a sophisticated sample bottle meant to hold a pre-established, pre-distribution vacuum, rendering it "ultraclean" and devoid of all moisture and impurities. The bottle's nozzle is attached to a sample tube, the other end is inserted into the sampling valve, and the nozzle is turned to release the vacuum, which sucks oil into the bottle. This approach does not need a standard hand-pump vacuum pump and may be used for any lubricating system, including pressurized systems.

The Condition Monitoring Pod is a multifaceted piece of equipment that lets an inspector perform many tasks from the same port. The CMP, also known as a "multi-parameter inspection pod," combines an oil sight glass and a sample port into a single piece of equipment. The CMP lets you view oil levels, color, clarity, aerating and foaming, corrosion, varnish, and wear debris. An oil sample may be drawn through the built-in, vacuum pump-compatible sample port. The CMP incorporates a stainless-steel pilot tube that may be bent inside the machine to the appropriate sample position.

Oil Sampling Methods

Pressurized Line

Sampling a pressurized line on an engine equals sampling a pressurized line on any industrial forced lube system. The lubricant is extracted from the sump and pushed through a filter before being distributed to the needed lubrication spots through a pump. The goal is to install sampling hardware in the live zone at a turbulent point past the pump and before the filter.

When sampling is required, the hardware is utilized while the system operates, creating a representative, repeatable sample. Installing sampling gear helps to maintain a closed system, allowing the sample to be retrieved without opening the system and jeopardizing its purity from outside factors.

Drop Tube

Drop-tube vacuum sampling is a straightforward, low-cost method of obtaining oil analysis samples. This method requires a large fluid flushing volume, needs help getting consistent samples from the exact location, and needs help sampling high-viscosity fluids.

The location will always be in the same general vicinity when using this method in conjunction with a dipstick tube. The existing variable is the depth at which the tube is inserted into the volume of oil in the sump.

To solve the issue of tube depth, insert a premeasured or graded sample tube to a known depth, which will limit the tube's termination point to a suitable area of changeable location.

Drain Port Engine Oil Sampling

Another way is to collect a sample of oil as it drains from the sump. The theory is that by catching the sample midstream, after purging a large volume of oil from the sump before filling the sample bottle, the sample taken resembles a sample representative of the system.

Although this approach provides cleaner sampling when obtaining a midstream sample, data collected from a drain port should be interpreted. This method is performed when the oil is replaced with new oil. Under typical operating conditions, this does not apply to trending the in-service oil

Every engine oil sampling procedure has various methods and associated variables. To be successful, it is necessary to understand the limitations and variability of each system and assume the appropriate amount of accuracy with each.

Implementing a World-Class Lubrication Program

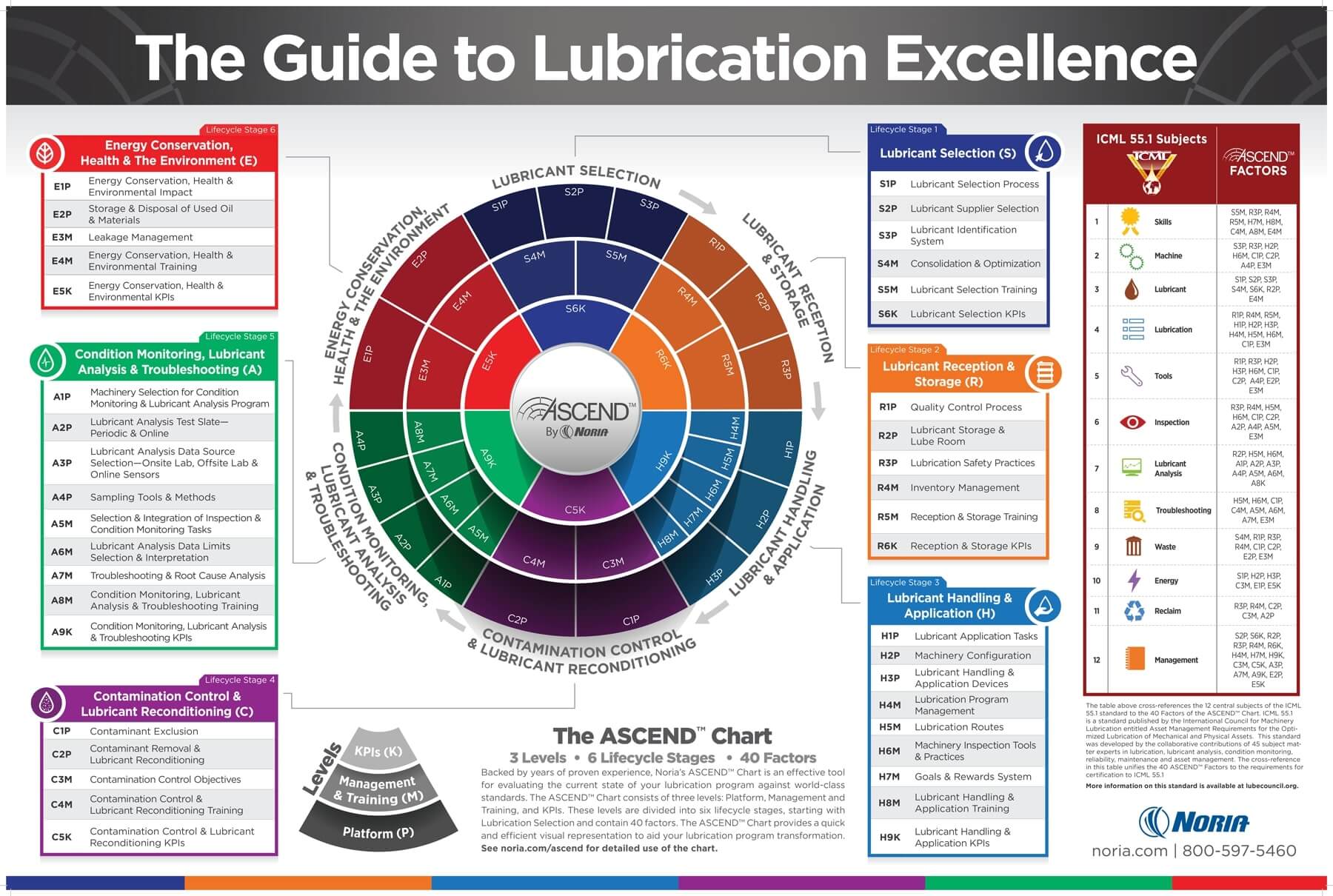

With CRE Philippines, all lubrication-related work processes and procedures, from purchasing down to the required re-grease volume for every bearing in the plant, can be addressed with our lubrication program designed by our partner, Noria.

Furthermore, implementing lubrication programs to diagnose incipient machine failure through oil analysis entails cost. As such, thorough planning must ensure that your resources are well-spent.

You will be confident to start your Machine Diagnostics Program and Lubrication Program with our full support every step of the way.

Sources:

Noria Corporation. (n.d.). 3 Engine Oil Sampling Methods. MachineryLubrication.

Trout, J. (n.d.). A Guide to Oil Sampling Hardware. MachineryLubrication. Retrieved from https://www.machinerylubrication.com/oil-sampling-hardware-31620