Oil analysis is an incredibly useful tool in today’s maintenance and reliability initiatives. But over testing can soon become costly and inadequate testing can result in information being of little use. When applied in conjunction with a sound plan, oil analysis can yield greater productivity, longer asset life, and higher profitability.

Overtesting

In today’s dependability initiatives, oil analysis is a very helpful instrument. Over-testing may quickly become expensive, and little testing might result in irrelevant information. To produce considerable outcomes while avoiding unnecessary costs, it helps to set up a criticality ranking of all your lubricated assets.

Calculating the Machine’s Overall Criticality

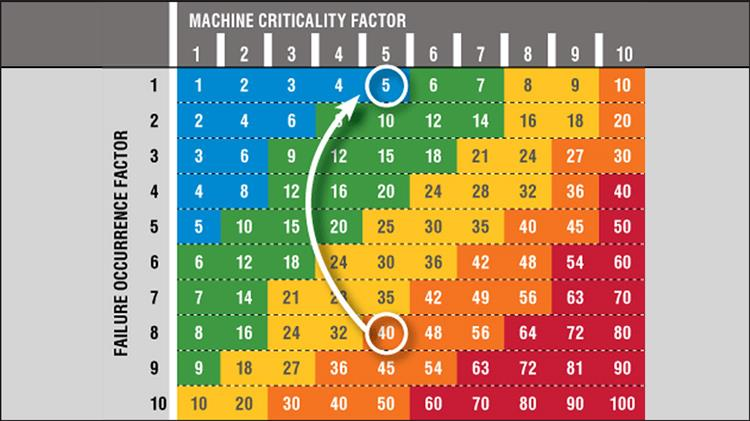

Overall Machine Criticality (OMC) is a statistic used in a variety of reliability and maintenance assessments, including oil analysis and other machine condition monitoring techniques. On average, important equipment requires more frequent inspection than less critical equipment. In terms of lubrication, the OMC assesses criticality. The Machine Criticality Factor (MCF), which illustrates the consequences of a machine failure, is multiplied by the Failure Occurrence Factor (FOF), which indicates the risk of a failure.

Recognize How Reliability and Risk Connect

Understanding failure modes and machine criticality can help you adjust your lubrication and oil analysis decisions. Develop a master strategy for lubrication-enabled machine dependability as part of your risk management strategies.

Although this will be the main emphasis of this post, there are other options you can employ to minimize the risks:

- Selecting lubricants, such as luxury lubricants vs budget lubricants

- Filter quality, pore size, capture efficiency, placement, and flow velocity all impact filtration.

- Preventive maintenance (daily PMs) and inspection approach for lubricants

- Selection and application methods for lubricants (e.g., circulating, auto-lube, mist, etc.)

- Which instruments are included in oil analysis, and which are excluded?

- Frequency of oil sampling (weekly, monthly, quarterly, never)

- There are several test and laboratory slates accessible.

- Limits and warnings for oil analysis

The Optimum Reference State must incorporate all of these decisions and behaviors. As a result, you should not underestimate the value of critical thinking. However, academics have not yet developed a practical method to assign value to criticality specifically for machine lubrication and tribology.

Lubrication and tribology present unique criticality issues and concerns that rarely appear in other types of equipment.

Machine Criticality in General

As defined by Industrial Service Solutions, The overall machine criticality (OMC) is a risk-profile assessment that may be simplified to a single number. When the OMC lowers, the danger reduces. The OMC is calculated by multiplying the Machine Criticality Factor (MCF) by the Failure Occurrence Factor (FOF).

Taking Action

There are three types of oil analysis:

- Set Targets

- Collecting samples according to the best practices

- Make sure that your test package includes the most appropriate parameters to help you capture the problem

- Utilizing On-site Testing especially when you’re facing logistics issues.

- Explore online Testing–Specialty meters (usually particle counts), moisture meters, and dielectric testers are installed in a circulating system to capture “live” lubricant conditions. In the last five years, this technology, like on-site testing equipment, has evolved substantially.

- Utilize other CBM technologies.

Each of the basic types of oil analysis has a distinct function and, when applied properly, may give a significant benefit to the end-user. Using a predetermined method to assign machine criticality provides an appropriate starting point for the decision-making process.

- Choose a machine

- Reliability targets

- Selection of a test slate

- Frequency of sampling

The days of a set test schedule and frequency are no longer with us. The best ROI comes from using criticality to fine-tune an existing program and get a new program off to a great start. Any plant that does not have a specified criticality assigned to machinery should examine this essential element. Without it, the predictability and ROI of the predictive program are at risk of falling short of expectations.

Understanding Criticality

Risk and criticality can be used to create a master plan for lubrication-enabled machine dependability. Commercial aviation is an excellent example. Maintenance personnel typically have little influence over the repercussions of failure. Reliability maintainers typically have a lot of influence on the likelihood of failure.

This is a list of common lubrication and oil analysis procedures that can be improved by understanding the failure modes and machine criticality:

- Choosing lubricants, such as premium vs. economy-formulated lubricants

- Filter quality, pore size, capture efficiency, placement, and flow rate are all factors infiltration.

- Preventive maintenance and inspection approach for lubricants

- Selection and use of lubricant delivery methods

- Oil Analysis

- Frequency of oil sampling

- Selection of test and laboratory slates

- Limits and alerts for oil analysis

CRE MachineDiagnostics™ Program

With CRE, you can start your CRE MachineDiagnostics™ Program with oil analysis, knowing that you’ll have our complete support every step of the way. Our package also includes a complimentary Machine Wear Analysis Basic Seminar to ensure your employees understand lubrication best practices.

We also have a dedicated support team that takes care of any issues you may have with our reports. Whenever you want a more in-depth explanation or detailed actionable recommendations, you will have easy access to the assistance of our skilled and globally recognized Lube Analysts and Machinery Lubrication Consultants.