Enhance your machinery’s performance and reliability with our blog on Oil and Vibration Analysis. Discover how integrating vibration and oil analysis can optimize your maintenance strategy, ensuring the longevity and optimal performance of your industrial equipment.

In industrial maintenance and reliability, ensuring optimal performance and longevity of machinery is paramount. One crucial aspect of this maintenance is oil vibration analysis, a sophisticated technique used to assess the health of machinery by analyzing the vibrations transmitted through lubricating oil. This method not only aids in diagnosing potential issues but also plays a pivotal role in predictive maintenance strategies, thereby preventing costly breakdowns and downtime. According to Machinery Lubrication, we will discover how vibration analysis and oil analysis can optimize maintenance strategy and reliability.

Vibration and oil analysis have proven to be effective predictive maintenance methods for decades. Maintenance teams can also apply thermography and sensory inspections. However, technicians must analyze each asset from multiple perspectives to determine the ideal maintenance approach.

Vibration Analysis

One well-known technique for identifying machine malfunction and confirming post-intervention machine acceptance is vibration analysis. Vibration analysis works with a variety of rotating equipment, including compressors, turbines, power generators, fans, pumps, reducers, and electric motors. It also detects problems such as imbalance, misalignment, mechanical clearances, warped shafts, damaged bearings, gears, cavitation, and lubrication faults in belts. Additionally, the technique can identify resonance in static structures in more complex applications.

Vibration analysis has various advantages, having non-destructive or non-invasive procedures covering almost 80 percent of a plant’s machinery. Maintenance teams can use the results to promote various changes. This includes enhanced alignment, better foundation conditions, higher-quality balancing, and the reduction or even elimination of persistent machine problems.

Using vibration analysis tools, technicians can observe machine fault modes. Common vibration analysis tools include kurtosis, rapid Fourier transform, envelope analysis, and spectrum analysis. Using these tools, technicians can identify failure modes such as imbalance by one rotation (1x) and misalignment by one or two rotations (1x and 2x). They also allow monitoring of different fault modes over time.

A high-spectrum carpet value is frequently indicative of contamination, excess, or lack of lubrication. Integration of the vibration analysis and lubrication teams can lead to effective control of these cases.

At a frequency spectrum of 0.42 to 0.48 times the revolutions per minute (rpm), technicians can detect problems in sliding bearings operating with high-pressure oil. Adjusting the oil speed can reduce or eliminate the wear caused by these faults, which force the shaft into the bearing and accelerate wear.

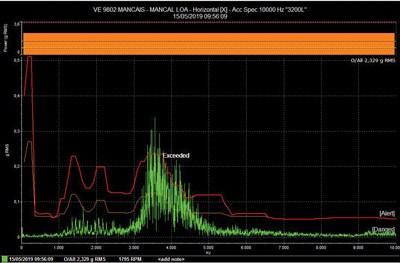

Figure 1: A bearing vibration spectrum before lubrication, Image Source: Machinery Lubrication

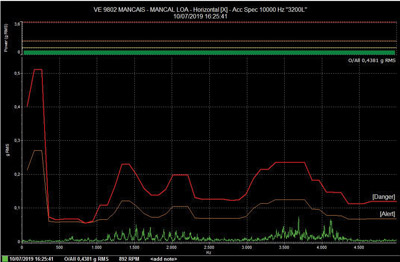

Figure 2: A bearing vibration spectrum after lubrication, Image Source: Machinery Lubrication

A high-spectrum carpet value is frequently a sign of lubricant failure. This is often due by contamination, excess, or lack of lubricant. When lubrication and vibration analysis team work together, these instances can be effectively controlled. When oil is running under high pressure in sliding bearings, it can cause wear faster than expected. The symptoms of an oil vortex, also called a dry vortex, appear as frequency spectrum shifts of 0.42 to 0.48 times the revolutions per minute. Fortunately, adjusting the oil speed can reduce or eliminate these effects.

The critical machine speed and the oil whirl frequency coincide to produce oil instability, a severe situation that results in bearing play. Consequently, oil whip, a more severe whirlwind, occurs when the vortex maintains the crucial rotor speed at higher speeds, causing significant damage.

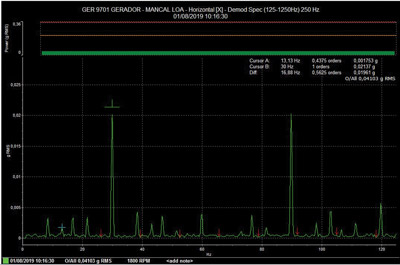

Figure 3. Oil instability frequency, Image Source: Machinery Lubrication

Improper lubrication can also result in rolling vibrations. The friction between the bearing and the shaft causes the carpet to rise, as can be seen clearly in the spectrum. Other machine frequencies can also be excited by this frictional force. The so-called carpet symptom is seen in Figures 1-2.

A scenario of mild oil instability that is still within allowable bounds is depicted in Figure 3. This frequency originates from a power generator’s bearing. It can be used as a target for monitoring since it shows the machine’s health.

Oil Analysis

Oil analysis is an essential method for determining the state of equipment and enhancing asset dependability. It is especially helpful for keeping an eye on hydraulic systems, pumps, transformers, compressors, turbines, and reducers. Particles produced by ongoing friction in machine parts, which are normally charged by the lubricant, can be identified with the aid of oil analysis. Having this knowledge is essential to preserving asset reliability.

Parameters for oil analysis are chosen based on machine characteristics and are an essential instrument for monitoring lubricant failures. Selecting the right tests and tailoring each one for a particular type of equipment is crucial for detecting anomalous oil wear particles. Techniques like particle counting and trend analysis are crucial for assessing the degree and condition of lubricants and determining whether to take action. Although the problem’s severity is quantified by global values, the problem’s frequency spectrum is also utilized to describe it. You can explore our previous article about “The Significance of Oil Analysis and Particle Counting”.

During oil analysis, technicians observe particle shapes to identify iron in samples. Additionally, changes in vibration readings and large particles signal the onset of wear. Viscosity, particle count, water content, acid number, base number, and particle size are examples of common oil analysis categories. Equipment wear and tear is accelerated by water in oil and necessitates immediate attention. This pollutant is harsh to machine components and necessitates quick action because it causes oil oxidation and friction between metals.

A good lubrication plan should clearly outline the sampling process, including collecting, storing, and transporting oil samples. This is to guarantee the accuracy of the analysis result. Lubrication technicians should be trained in these tasks, and they must handle sample submission and identification carefully.

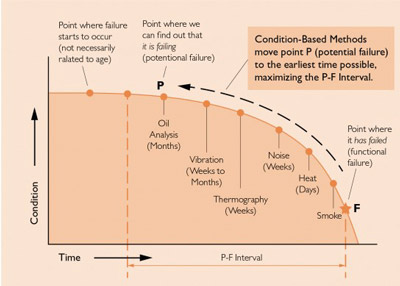

As shown in Figure 4, oil analysis often detects bearing failure in low-speed gearboxes before vibration analysis does.

Figure 5. The quality of sample collection determines the quality of the analysis., Image Source: Machinery Lubrication

Oil analysis helps identify increasing metal particles and mineral impurities early in low-speed gearboxes. Additionally, it can detect bearing failure before vibration analysis reveals any issues.

Vibration Analysis vs. Oil Analysis

Vibration and oil analysis are complementing methods for asset condition reliability and root cause analysis. Together, they are highly effective in detecting pinion tooth wear and bearing lubrication failure. Oil analysis detects water in oil, whereas vibration analysis identifies imbalance and misalignment. Both methods are crucial for guaranteeing asset dependability and averting any problems, which makes them necessary in maintenance programs. To understand more about these two predictive maintenance methods, you can also check our previous blog “Oil Analysis vs. Vibration Analysis: When and Why to Choose Each Technique”.

Case Study: Low-Speed Gearbox Analysis

The primary factory of a South American vegetable protein manufacturer faces outside contamination during the rainy summer and winter. However, early oil analysis enabled the maintenance team to install protective devices, thereby blocking contamination and achieving measurable improvements.

Oil analysis reports would show alerts that other predictive maintenance approaches did not pick up on. The facility quickly realized that oil analysis could identify problems before the other techniques could.

For instance, the chromium value went from 0.10 ppm to 0.83 ppm in the oil analysis results for a soybean elevator reducer, yet the iron content jumped from 65 to 527 parts per million (ppm). This was a clear sign of bearing wear.

In the same month, the gearbox’s vibration analysis results were within normal limits. The increase in vibration readings that indicated an input shaft bearing failure didn’t show up for over a month.

The workers at the company made the decision to repair the damaged oil and bearing in the machine after considering this information. The modified bearing’s rolling components speak to the effectiveness of both strategies. Following the replacement of the oil and bearings, the vibration study revealed no flaws.

Combining vibration and oil analysis has produced positive outcomes for the facility. Productivity has increased and there have been fewer breakdowns. Managing faults and coordinating interventions with production planning reduces downtime. Furthermore, replacing lubricating oil and components only as needed extends machine life. Balanced plant equipment uses less energy and vibrates less. Even more durable are parts like seals and bearings.

Conclusion

Vibration analysis and oil analysis have shown to be useful methods for keeping an eye on the condition of assets. Although numerous studies have demonstrated that oil analysis can offer an early warning system for possible problems, the best outcomes come from combining these two approaches, which makes them both essential components of modern maintenance programs.

Businesses can reduce expenses, minimize risks, and guarantee continuous production cycles by utilizing vibrational and oil analysis. For those looking to deepen their understanding and proficiency in vibration analysis, consider exploring comprehensive training programs offered by CRE Philippines. Our Vibration Analysis Training equips participants with the skills and knowledge necessary to implement effective predictive maintenance strategies, ensuring the continued reliability and performance of critical machinery.

We also offer Oil Analysis Certification Training Program that provides in-depth knowledge on oil analysis techniques and their applications.

If you’re ready to enhance your maintenance skills and ensure the reliability of your machinery, contact us and join our comprehensive training programs. Our expert-led courses in vibration analysis and oil analysis certification provide the knowledge and tools you need to implement effective predictive maintenance strategies. Your path to superior machinery performance and reliability starts here!