Amid today's evolving industrial landscape, where machinery is central to manufacturing and transportation sectors, the significance of optimal machine functionality cannot be overstated.

This significance finds its audience among maintenance professionals, the unsung heroes responsible for the seamless operation of these mechanical giants. Amidst the multifaceted realm of machinery maintenance, there exists an often underestimated facet - lubrication, a fundamental process that stands as the vanguard against friction-induced wear and tear

The Greater Significance of Small Particles

When discussing machinery lubrication, the size of particles suspended within the lubricating fluid might not be the first thing that comes to mind. But as we delve deeper, it becomes evident that the size of particles plays a crucial role in determining the health and performance of the machinery. Small particles, often invisible to the naked eye, have the potential to cause significant disruptions in machinery operation.

The Impact of Particle Size

Understanding the impact of particle size begins with realizing that smaller particles can penetrate the tightest clearances and crevices within machinery components. These particles can exert mechanical stress on surfaces, increasing wear and catastrophic failures over time. As machinery components wear down, the entire system's efficiency diminishes, resulting in decreased productivity and higher maintenance costs.

The Intricacies of Particle Ingestion

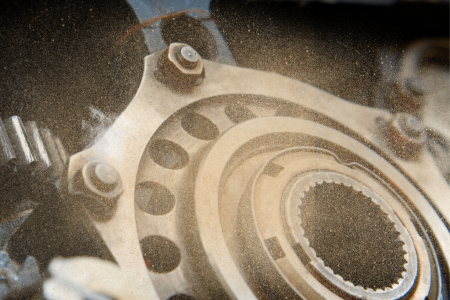

Particles aren't only external contaminants; they can also be generated within the machinery. Dust, rust, and debris contaminants can infiltrate lubrication systems and accumulate over time. The lubricant ingests these particles and is transported throughout the machinery, wreaking havoc on delicate components. As particle concentration increases, the potential for machinery malfunction rises.

Unraveling the Consequences

The ingestion of particles doesn't only lead to physical wear and tear. It can also instigate chemical reactions that degrade the lubricating fluid's quality. As lubricants break down, their ability to provide adequate lubrication diminishes, putting more stress on machinery components. This vicious cycle can result in a cascading effect, leading to accelerated machinery deterioration.

The Role of Mechanical Processes

Mechanical processes within machinery, such as friction between moving parts, can generate particles of various sizes. Often, microscopic particles can combine with lubricating fluids to form abrasive compounds. Over time, these abrasive compounds exacerbate machinery wear, causing premature failure and decreased efficiency. Particle counting becomes essential in such scenarios, as it enables maintenance professionals to track and mitigate the effects of these particles.

Are Your Machines Experiencing Problems?

In the grand tapestry of machinery maintenance, particle counting within lubrication systems emerges as a cornerstone of paramount importance. The subtle nature of small particles belies their potential to wreak havoc on machinery components. By grasping the nuances of particle size impact and adopting effective particle counting techniques, maintenance professionals are armed with the proactive measures needed to avert machinery breakdowns and extend equipment lifespans. Whether overseeing an expansive manufacturing domain with robust machinery or managing a fleet of vehicles traversing vast distances, the wisdom drawn from particle counting resonates.

Regular analysis and vigilant particle monitoring can preempt emerging issues, curtailing unplanned downtime incidents and reining maintenance costs. Knowledge emerges as the fulcrum of control as we navigate the complex realm of machinery lubrication, where even the tiniest particles can orchestrate monumental disturbances. Implementing a holistic particle counting strategy transcends risk mitigation; it engenders a culture of proactive maintenance, ensuring machinery operates at its zenith capacity. As you continue your machinery maintenance journey, bear in mind the microscopic entities capable of wielding colossal influence. Embrace particle counting as an indispensable tool in your maintenance repertoire, witnessing your machinery flourish under your vigilant care. For those seeking a comprehensive oil analysis program to track machinery well-being, CRE MachineDiagnostics™ Program beckons, offering an avenue to elevate maintenance practices and embark on a path of amplified reliability and efficiency. If you want to take your maintenance practices to the next level, don't hesitate to contact us for more information.

Source:

Richardson, T. (2022, June). Particle Counting: Why Smaller Particles Lead to Big Trouble. Machinery Lubrication. https://www.machinerylubrication.com/Read/32156/particle-counting-why-smaller-particles-lead-to-big-trouble-