The designs of many common machine mechanisms have stayed the same for decades. Machine designers working for Original Equipment Manufacturers (OEMs) believe lubrication may improve.

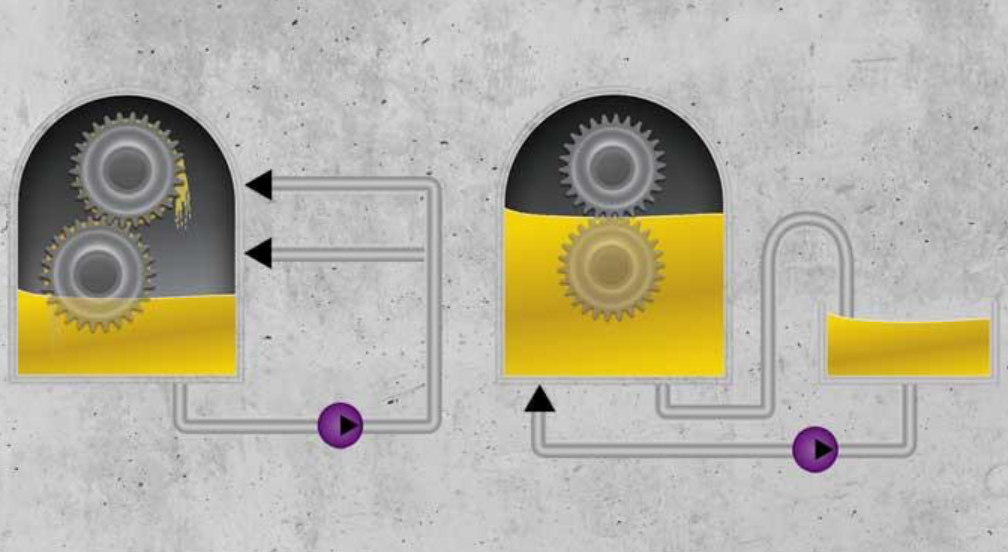

There are new machines created today based on this incorrect notion. Several wet-sump oil systems have visible evidence in pumps, gears, and bearings.

Source: machinerylubrication.com

Source: machinerylubrication.com

Several non-circulating bearing and gear sumps that feed oil to frictional surfaces are good examples. These are Wet-sump Lubrication (WSL) systems that use one of the following methods to deliver lubricants:

- Climbing-Oil Lubrication – the rotation of gears in a wet sump lift adhering oil into gear mesh zones.

- Flood Lubrication – oil is used to immerse frictional surfaces.

- Oil Ring/Collar Lubrication – oil is lifted to the top of channels and grooves by spinning rings and collars, where gravity feeds it into bearings.

- Slinger/Flinger Lubrication – moving objects toss oil to troughs and frictional zones.

- Splash Lubrication – gear movement through an oil sump causes a splash or mist to spread throughout the gear set, wetting machine surfaces.

All these methods provide little more than a primary lubricant supply. Today's reliability organizations demand more than this, especially for machines prone to failure or with high machine criticality. Retrofitting an oil circulation unit to an existing wet-sump system is a simple upgrade many users may make.

Users and machine designers only sometimes understand circulation benefits. This is one of the reasons why OEMs and customers alike reject the extra cost of oil circulation as a required investment.

Oil circulation systems are classified into four types:

- Oil-feed Circulation – a wet-sump system that directs lubricant to lubricated surfaces by pumping oil from the sump through lines.

- Constant-level circulation - uses a small external reservoir and the machine's wet sump.

- Offline circulation - is a simple kidney-loop system that controls offline filtration and temperature.

- Hydraulic system – a flooded system in which frictional surfaces contact the circulating oil.

Hydraulic and oil-feed circulation are complex systems in design and production. But, consumers may get many benefits from oil circulation by adding constant-level and offline circulation to most WSL machines.

Benefits

As mentioned, many benefits of oil circulation are subtle or need to be more understood. Yet, they are critical to machine dependability. Some of the benefits of oil circulation are detailed in further detail below for a better understanding:

Contamination Control

It is not easy to maintain oil cleanliness and dryness without onboard. Filtering necessitates oil circulation, which wet-sump lubrication does not provide. The only other option would be to use portable filter carts to clean the oil and flush the sump.

Onboard filtration is superior and should be included in constant and offline circulation. Filtration has the extra benefit of reducing pollutant levels even when the machine is idle.

Minimal Risk of Sediment and Free Water

Flowing oil disrupts settling zones, which allow sludge and silt to collect. These pollutants are instead trapped in the filter. Many wet-sump systems accumulate more sediment than oil in the sump, which is hard to detect. Sediment can be disturbed by machine movement, oil turbulence, and oil drain-and-refill processes.

The fishbowl effect, which causes disturbed sediment to travel to critical zones in the machine, can cause unexpected machine failure. Water vapor is also released into the environment when oil is circulated. Water puddles on the sump floor in simple wet-sump systems over time.

New Oil Filtration

When fresh oil is transported to a wet sump, it is usually unfiltered and from a dirty transfer container. All oil entering the sump must pass through the filter when filters are placed on constant-level circulation systems. If there is ambiguity on the purity of fresh oil, this ensures a higher level of contamination control.

Offline circulation systems can also be equipped with quick connects and valves, allowing new oil to be injected into the sump via the filter in the offline loop.

Oil Volume Benefits

Filters and piping add fluid to the circulating system. When, for example, you have twice as much fluid, you have twice as much additive, half as many contaminants, half as much wear metal, half as much thermal damage to the oil and a lower oil temperature.

Remember that a constant-level circulation system with an external reservoir can be used instead of an offline circulation system to reap the benefits of greater oil volume.

Oil Analysis Program

Establishing maintenance plans to detect early equipment failure through oil analysis is costly. As a result, careful preparation is required to guarantee that your resources are well-spent.

With CRE, you can start your MachineDiagnostics™ Program, knowing you will have our full support at every step. Our package includes a complimentary lecture, Machine Wear Analysis Basic Seminar, to ensure your employees know the optimal lubrication techniques. We also have a dedicated support team that handles all your concerns on our reports. You will also have easy access to the advice of our capable and certified Lube Analysts and Machinery Lubrication Consultants whenever you need more in-depth explanations and comprehensive, actionable recommendations.

CRE Philippines also offers a test package called GearCheck™ 884. The package tests the condition of oil, contamination, and wear. It also includes special tests on double wear checks and ferrographic analysis to help you narrow down the root cause of gear problems. Contact us here to know more.

Source:

Fitch, J. (n.d.). Add Oil Circulation to Gear and Bearing Sumps for Greater Reliability. MachineryLubrication. Retrieved from https://www.machinerylubrication.com/Read/29453/circulation-gear-sumps