Oil analysis reports are critical tools for maintenance professionals responsible for the health and performance of industrial equipment.

Experts can identify potential problems and take corrective actions before the equipment fails by analyzing the properties and composition of oil samples taken from the equipment. But, understanding oil analysis reports can be challenging for those new to the process. This article will explore the basics of oil analysis interpretation, including what information can be obtained from an oil analysis report, how to interpret the results, and what actions should be taken based on the analysis.

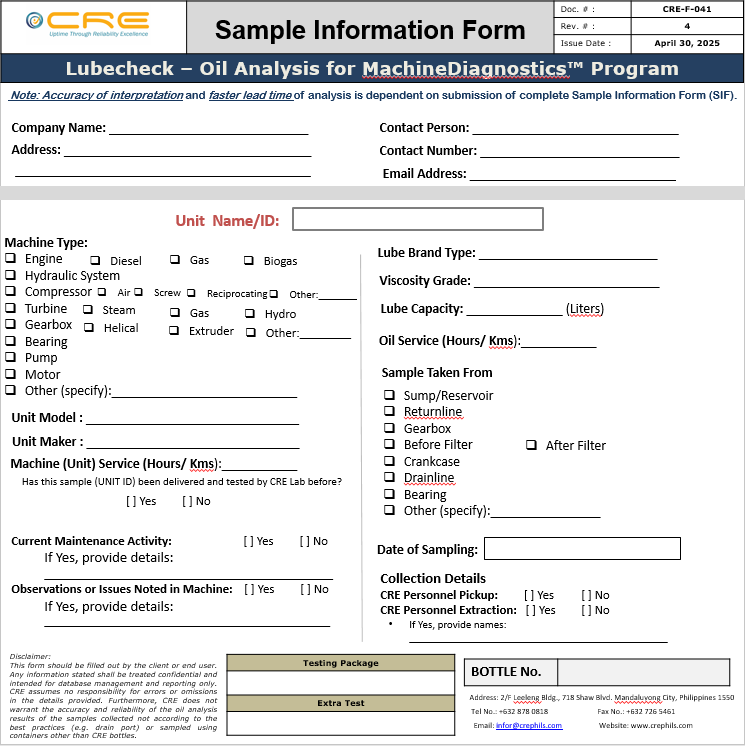

Sample Information Form (SIF)

Before the oil analysis report can be generated, the company sending samples for testing must fill out the SIF. The SIF is a crucial component of the oil analysis process, as it provides the laboratory with essential information regarding the equipment and the oil being tested. The form typically includes details such as the make and model of the equipment, the type of oil used, and other relevant information that may impact the analysis results. It is essential that all information provided on the form is accurate and complete to ensure that the laboratory can generate the best possible analysis report.

When filling out the SIF, providing as much detail as possible regarding the equipment and the oil being tested is crucial. This includes information such as the age of the equipment, the operating conditions, and any recent maintenance that has been performed. Providing this information can help the laboratory better understand the conditions under which the oil operates, which can be critical to generating accurate analysis results.

Contents of the Report

The first section of the oil analysis report is the “Customer and Unit Information,” which contains essential details about the equipment and oil being tested. The information in the oil analysis report must match the details in the SIF submitted with the sample.

The “Overall Traffic Warning Light” on the right is an essential feature that provides a quick and easy-to-understand visual representation of the sample’s condition. The traffic light system uses three colors to indicate the overall status of the sample results: green for “Normal,” yellow for “Caution,” and red for “Warning.”

This system makes it simple to identify the sample’s status at a glance, even if individual test results have different statuses. For example, if only one test result indicates a “Warning” status, the overall status will still be in that range, clearly showing the sample’s condition.

The “Notes” section is the most critical part of the oil analysis report. The section typically begins by outlining the sample’s history, including information about the equipment, the oil used, and any recent maintenance or repairs. The laboratory then provides a detailed sample analysis, assessing contamination levels, wear, and other factors affecting the equipment’s performance. Based on these findings, the laboratory may recommend specific actions to improve the equipment’s reliability and meet the organization’s objectives, targets, and goals. For example, if dirt is present and results in wear, the laboratory may recommend checking the oil filtration system for proper operation and other components for the source of the dirt entry.

The “Sample Information” section provides essential details about the sample, including the bottle ID and the number of oil hours. This information is crucial for tracking the sample’s history and ensuring it is appropriately labeled and tracked throughout the testing process.

The “Baseline and Alarm Limits” section outlines the acceptable range of values for each test performed on the sample. These limits are based on the equipment manufacturer’s specifications, industry standards, and the laboratory’s experience and expertise.

The “Results” section of the oil analysis report is the most detailed section, providing valuable insights into the sample’s condition. This section is divided into three categories: Wear Condition, Oil Condition, and Contamination. Each category is labeled with only two symbols, “C” for caution and “W” for warning, allowing maintenance personnel to identify potential issues quickly.

The laboratory analysts use the “Baseline and Alarm Limits” section on the right to determine the acceptable range of values for each test and compare them to the actual results. The laboratory analysts then provide detailed explanations and recommendations based on the results outlined in the “Notes” section.

Interpreting the Results

Interpreting the results of an oil analysis can be complex and requires an understanding of the various tests performed and the significance of the results. The following sections offer an overview of some of the critical tests used in oil analysis and how to interpret the findings.

Viscosity

The viscosity of an oil is an indicator of its thickness. It is an essential property because it affects the ability of the oil to lubricate machine components. If the oil is too viscous, it may not be able to flow correctly through the machine, leading to increased wear on machine components. The oil may not offer appropriate lubrication if it is too thin.

The oil’s viscosity can be affected by several factors, including temperature, contamination, and wear. A significant change in viscosity can indicate a problem with the oil or the machinery. A decrease in viscosity can indicate contamination or wear, while an increase in viscosity can indicate oxidation or thermal breakdown.

Elemental analysis

The elemental analysis involves testing the oil for the presence of certain elements, such as iron, copper, and aluminum. These elements are found in machine components, and an increase in their presence in the oil may indicate wear on those components. Analyzing the type and amount of wear metals makes identifying the specific parts experiencing wear possible. For example, high iron levels can indicate wear in the bearings or gears.

Contamination analysis

Contamination analysis involves testing the oil for the presence of contaminants. These are unwanted substances that can be present in the oil, such as dirt, water, and fuel. Contamination can affect the lubricating properties of the oil, leading to increased wear on machine components. It can cause damage to the machinery and reduce the effectiveness of the lubricant. By analyzing the type and amount of contaminants present according to contamination limits set, it is possible to identify the source of the contamination and take appropriate action.

Acid number

The acid number is an indicator of the acidity of the oil. An increase in the acid number may indicate that the oil is degrading. Chemicals added to the oil to increase its performance are known as additives. Additives can include antioxidants, corrosion inhibitors, and detergents. By analyzing the levels of additives in the oil, it is possible to determine if the oil is performing as expected.

Interpretation Guidelines

No single set of guidelines can be applied to all situations. But some general guidelines can be used to help interpret the results of an oil analysis:

1. Understand the Context

Before diving into the report’s details, it’s essential to understand the context in which the oil sample was taken. This includes the type of equipment, the operating conditions, and the maintenance history. Understanding the context will help put the oil analysis results into perspective and identify potential problems.

2. Identify Trends

Oil analysis reports should be read over time to identify trends in the condition of the oil and equipment. By comparing the current analysis to previous analyses, it is possible to identify trends and changes in the condition of the oil and machinery. Comparing results from many samples over time can help identify potential problems early and track the effectiveness of corrective actions. Look for parameter trends such as viscosity, wear metals, and contamination levels.

3. Compare to benchmarks

Comparing the oil analysis results to benchmarks for similar machines or systems can be helpful. This can better understand whether the results are normal or abnormal.

4. Consider the application, age, and history of the machinery

The application of the machinery can impact the condition of the oil and the machinery. For example, machinery that operates in a dusty environment may experience higher levels of contamination. The age and history of the machinery can also provide important context for interpreting the oil analysis results.

5. Identify Abnormalities

Look for abnormalities in the results of the tests. Abnormalities can indicate potential problems, such as increased wear rates, lubricant degradation, or contamination. Common abnormalities to look for include high levels of wear metals, increased viscosity, and elevated acidity.

If abnormalities are found in the oil analysis results, it is vital to consider the severity of those abnormalities. For example, a slight increase in wear metals may not cause immediate concern, while a significant increase may indicate a severe problem.

6. Understand the Recommendations

Oil analysis reports often include recommendations for corrective actions. Understanding these recommendations and taking appropriate measures to address potential problems is essential. Recommendations may include changing the oil, cleaning the equipment, or replacing worn components.

7. Consult with Experts

If you need help interpreting an oil analysis report or need help understanding the results, consult experts. CRE Philippines can provide guidance and support for interpreting and acting on the oil analysis results.

Taking Action

Once the results of an oil analysis have been interpreted, it is vital to take appropriate action to address any issues that have been identified. The following are some actions that may be taken based on the results of an oil analysis:

- Change the oil: If the oil analysis indicates that it has degraded or is contaminated, it may be necessary to change the oil.

- Investigate further: If the oil analysis indicates a problem with the machinery, it may be necessary to investigate further to identify the cause of the problem.

- Schedule maintenance: If the oil analysis indicates that maintenance is needed, it is essential to schedule the maintenance as soon as possible to prevent further damage to the machinery.

- Adjust lubrication practices: If the oil analysis indicates that the lubrication practices are inadequate, it may be necessary to adjust those practices to ensure proper lubrication of machine components.

Programs

Keep your equipment running at peak performance with the CRE Philippines’ Oil Analysis Package. Our state-of-the-art laboratory provides accurate and reliable results, helping you identify potential issues and proactively prevent costly downtime and repairs. Please choose from our comprehensive range of test packages tailored to your specific needs and customize your testing program based on your equipment and operating conditions.

Our most popular test package is EngineCheck™ 894, which includes comprehensive condition tests for oil, contamination, and wear and special tests like Double Wear Check and Particle Count results in NAS 1638 & ISO 4406.

In addition to our comprehensive oil analysis services, CRE Philippines offers training programs to help you and your team become experts in equipment reliability and lubrication. With our training programs, you can equip yourself and your team with the knowledge and skills to optimize your equipment reliability program and prevent costly downtime. Contact us today to learn more!